1. Mahe port construction Victoria, Seychelles.

Project Details: The end uses is a French company,which had offices in Shanghai China. Before placing the order,client come to visit Grand Piling’s factory many times to finalize the details. Over 100 drawings were issued by Grand Piling. The project is divided into 2 phases. Totally 4200 tons of steel tie rods and accessories are needed for this project. Diameter from 50-100mm. Steel grade are high S700 in European standard. All tie rods are painted with epoxy paint in China factory and packed for export. To save costs, all goods are shipped by bulk vessels together with sheet piles,pipe piles.

2. Dock construction Hedland port, Australia.

Project Details: Grand Piling supplied sheet pile,steel tie rods, wailings and capping beams for this project. Total quantity is 755 tons.All shipment are done by one time in containers. Since all products and accessories are produced by us,all products are compatible well with each other. Capacity of the waling beam was designed to maintain a factor of safety of 1.2 in static conditions and 1.1 in seismic conditions. The Anchor Piles had no coating.Anchor Wall Component Capacities The design of the sheet pile system was performed in accordance with the requirements of BS5950-1. In determining required structural capacity, the full yield strength of the material was utilized. Capacity of the Main Wall Components will then be compared with the loads determined in Retaining Wall Design Calculations Report. Corrosion was considered for a period of 35 years. Coating Requirements The specified coating for the sheet piles is for shot blasting to SA2.5 followed by 2 layers of 250 micron Jotamastic 87.

3. Wharf Port Moresby PNG. 2011

Project Details: Diameter 65mm,steel grade 1030,with minimum yield strength 835Mpa,minimum tensile strength 1030 Mpa,One set is around 35m. totally 250 sets. Around 300 tons. This is the strongest steel for tie rod in the world up to now.Grand Steel sheet piling also supplied back to back welded wailings,2000 linear meters

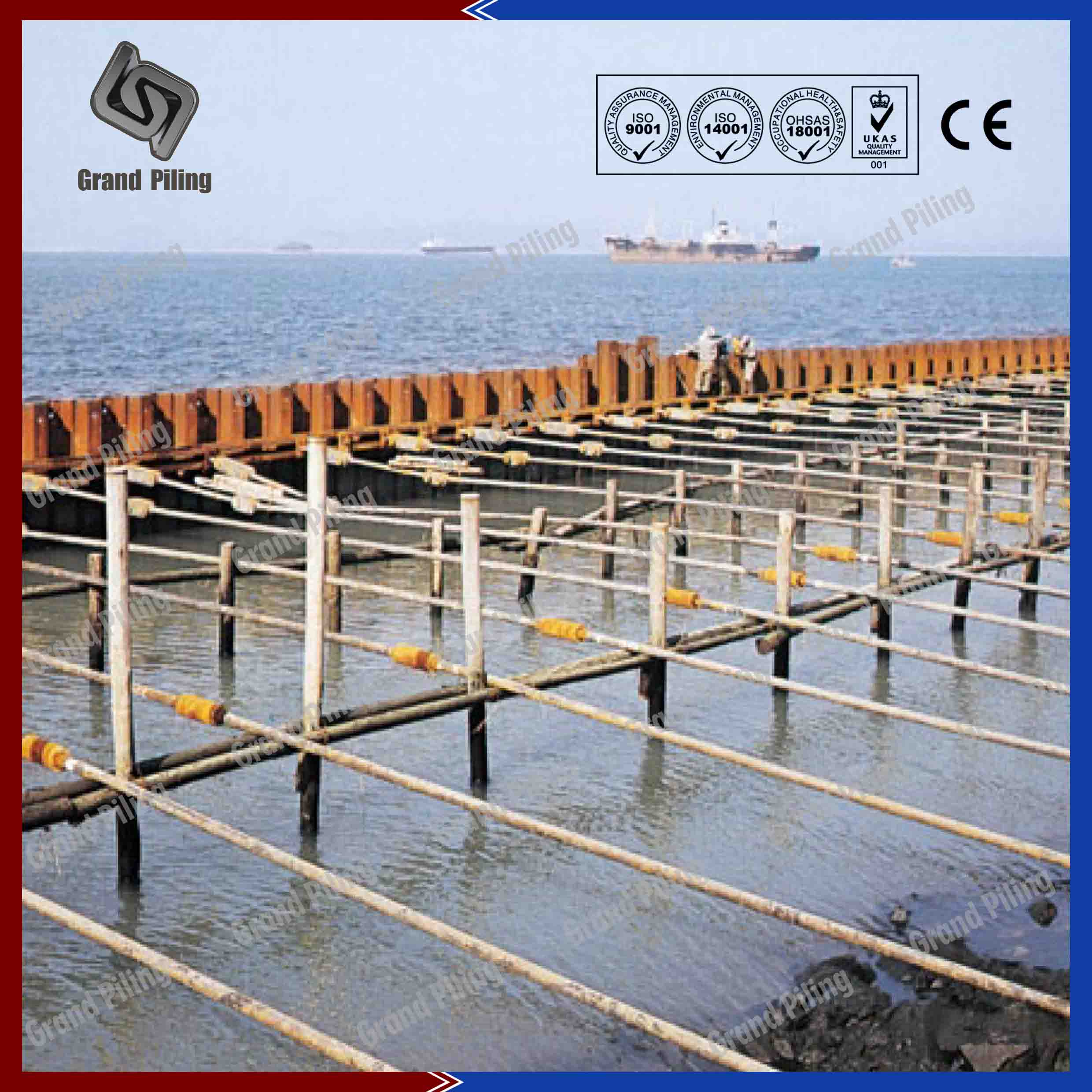

4. East Siberia- Pacific Ocean, Russia.

Project Details: This is for a big ship yard project, clients visited Grand Piling factory with the project owners.After face to face technical meeting between two parties’ engineers, the project owner accepted Grand Piling’s design. Total quantity is 4500 tons, supply frame is 6 month. Tie rod diameter from 50mm to 150mm,steel grade S700, with epoxy primer painting.This is one of the biggest tie rod projects Grand Piling has supplied. The tie rod design was performed in accordance with BS8081. Geotechnical loads were calculated from representative soil parameters and considered working load values. The effects of the various load cases were considered. Tie rod capacity was designed to have a factor of safety of 2.0 (uncorroded) and 1.75 (corroded) on static load conditions, and a factor of 1.1 applied in seismic conditions.All the marine tie rod works are produced in our factory in China. Separate additional tie rods provided for quick release hooks. No bollard loads were considered in the main tieback system. Corrosion of the tie rod system was considered for 35 years.

5. European Cup Stadium, Warsaw, Poland.

Project Details: Grand Piling visited Warsaw before the construction begins, and had numerous talks with the clients. The sheet pile used is AZ hot rolled sheet piles. Grand Piling also supplied the wailing and tie back systems. Totally over 5700 tons of tie backs and wailings, support console etc needed. This is one of main project we had one in Europe. The whole construction process is controlled and monitored by officials. This project won a big reputation for our projects in Europe.

6. Residential building, Bunschoten, the Netherlands. 2010

Project Details: Grand Steel Sheet Piling supplied steel wailers,609 steel pipe as the strut for the sheet piling structure.also threadbar ground anchor was provided.All sheet piles was from Grand steel piling's Netherlands stock.Totally 520 linear meters of wailings,and 35 pipes in S355 steel grade

7. Hudong-Zhonghua Shipping Goup China. 2008

Project Details: Size of Tie Rods: Φ90mm diameter,upset ends. Grade: 460 Amounts:484pcs Gross Weight: 616T.This was the first S460 steel tie rod produced by Chinese factory,until now,Grand Steel Piling still leads the way of piling industry.

8. Port of Melbourne, Australia. 2008

Project Details: The steel tie rod is to connect a HZ combiwall to a concrete deadman wall.Grand steel piling design and produce special joint for HZ beams,as bleow.Total weight 180 tons. Diameter 110mm,steel grade S550.Length per set 18m.

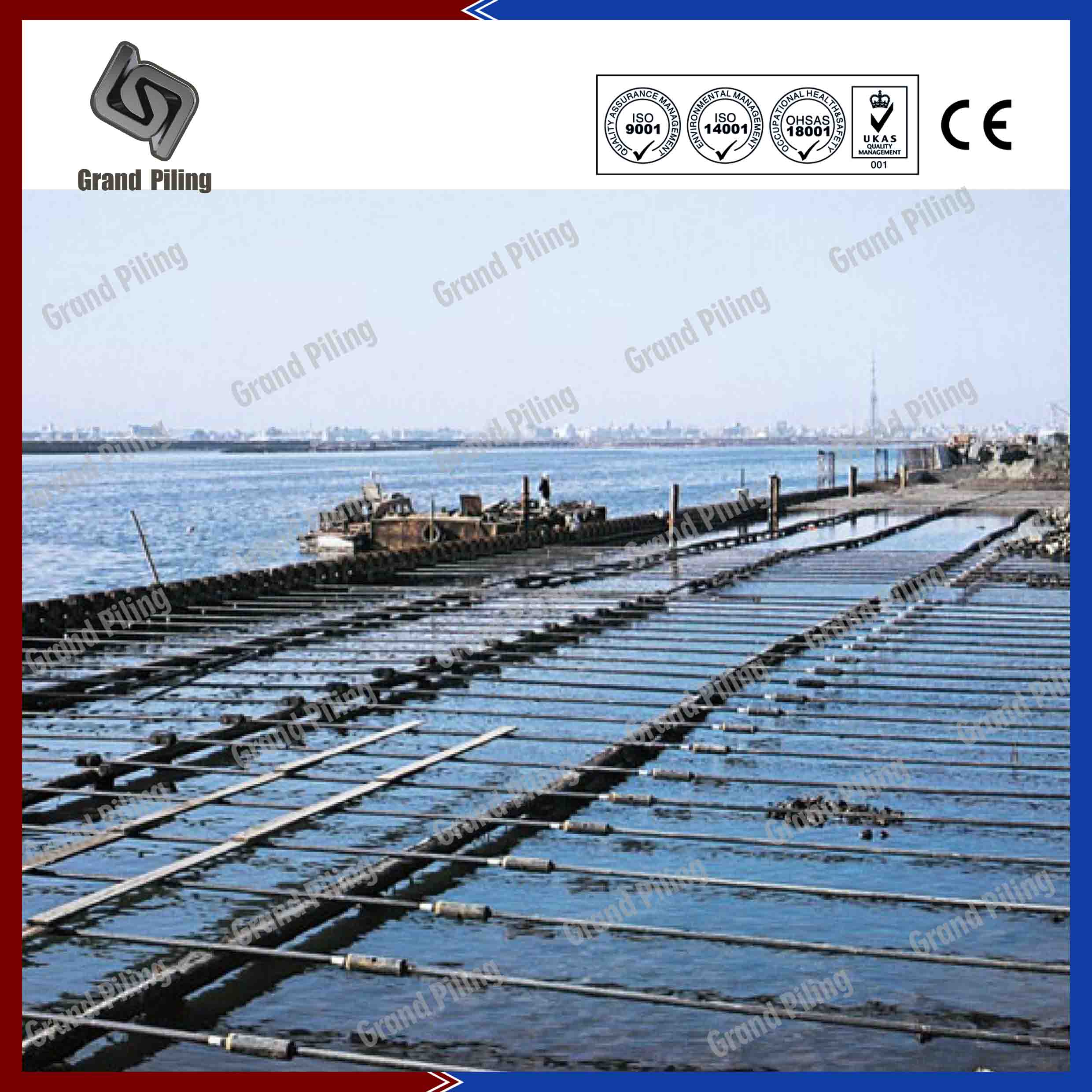

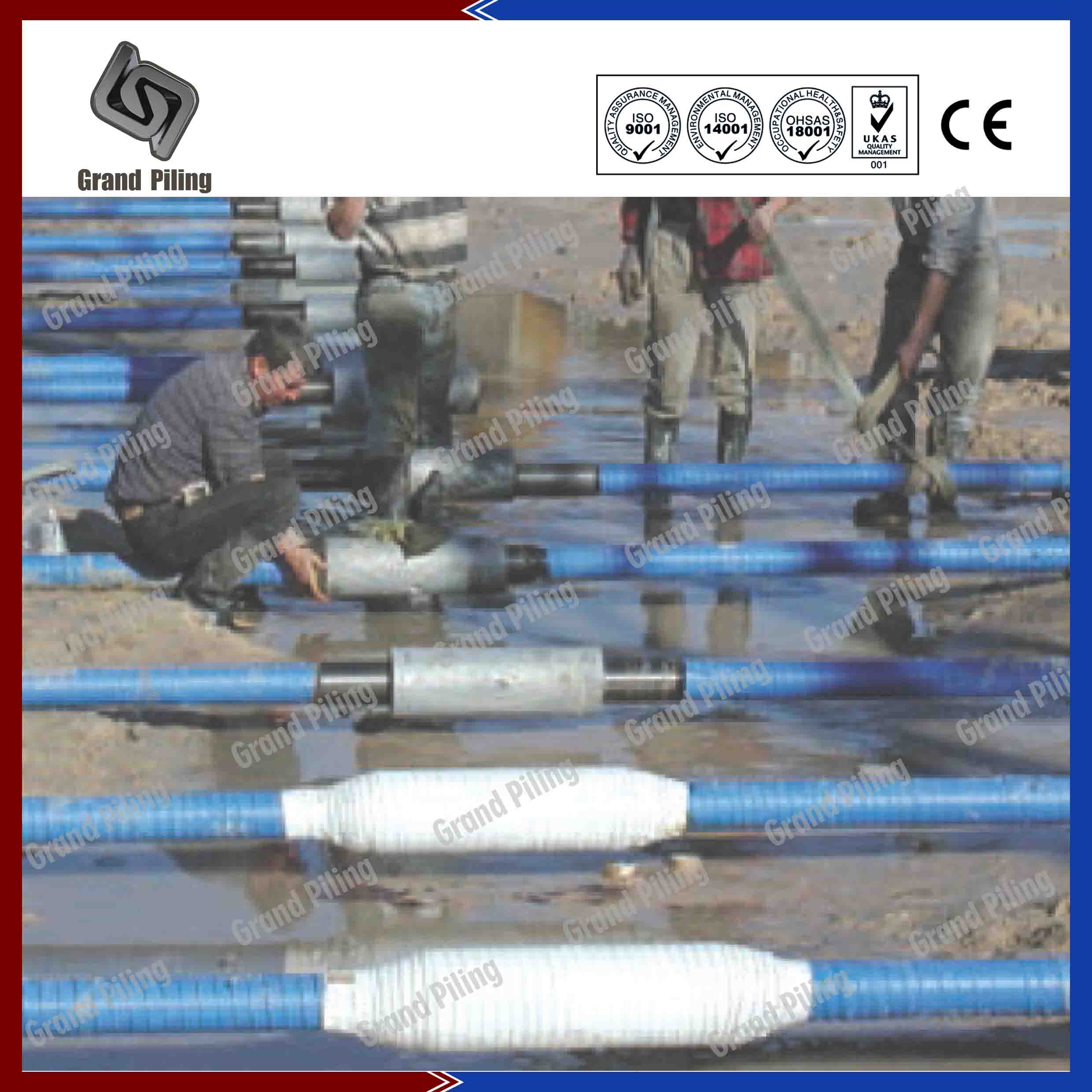

9. The Qasim port project in Pakistan. 2008-2009

Project Details: Steel tie rod diameter 115mm,upset threaded ends.The total length per set is 51.54m,with several turnbuckles and couplers so that the length can be adjusted.S550 steel grade,meaning the minimum yield strength is 550Ma,very high strength alloy steel. The first phase is in December 2008,140 sets or totally 800 tons was deliveried.Second phase is April 2009,308 sets ,1700 tons. Totally the contractor buys 2500 tons steel tie rod from us.

10. Cork Port, Ireland. 2008-2009

Project Details: Grand Steel Piling not only supplied steel sheet pile,but also H beams in 18m S460 steel grade. to be welded at back of sheet piles to achieve higher modulus of section.The H beam size was 800x300x14/26 210kg/m,modulus of section 7290cm3.total weight of all H beams is around 1800 tons.