Light sheet pile has been designing and producing since the late 1980’s, and are now a leading manufacturer of cold rolled/formed sheet piles, supplying a global network. The development of rolled corner sections has enabled a new generation of bearing pile to be created. Nippon Steel sheet piles are used for a wide range of construction projects, including port and harbor

construction, river improvement, earth retaining and cofferdams.

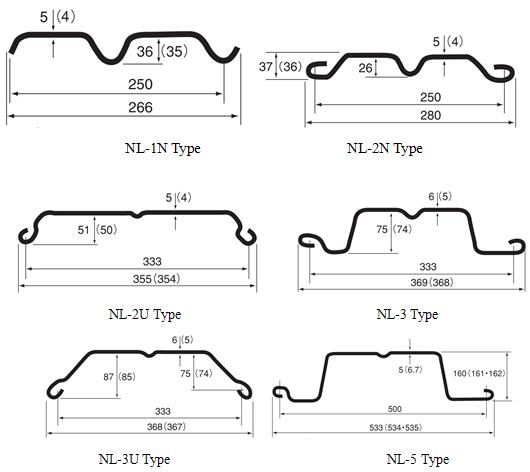

The Group has production facilities in Malaysia, China and The United Arab Emirates. Production times are fast and product quality guaranteed.By interlocking a number of sheet piles with the same number of Omega bars a closed tube results which can be driven into the ground sequentially.NL-1N,NL-2N,NL-2U are highly rated for their excellent quality and exceptional work efficiency.

The objective of the steel sheet pile is to use our wide range of expertise to provide customers with efficient and quality products and services that meet their stated and implied requirements. Using equipment that installs piles without noise and vibration, the ability to drive a closed section pile by pile means that load bearing foundations made of steel can be installed at sensitive sites and in urban areas where impact driven piles would not be tolerated.Nippon Steel, drawing on a wealth of rolling, fabrication and application technologies amassed over the years and further adding to the superb properties of its sheet piles, has recently developed various new products and

construction methods in this field, which have also won for the company a high reputation.

The approach to sheet piles is orientated on the customers requirements. In addition to the reduction in environmental disturbance offered by this system, the foundation is effectively load tested as it is installed and can be loaded immediately. NL-3,NL-3U,NL-5N believe that simply supplying a product is insufficient, therefore the level of support a customer receives when they are considering purchasing products is unprecedented. Nippon Steel will continue its efforts to develop novel products that bring the properties of sheet piles into full play and to respond to more stringent and diversifying user needs in the future.

This ranges from general advice on the Client’s options to full engineering support and design, and includes necessary accessories such as painting, tie rods and other items associated with sheet piling works. The prefabricated sheet pile cell construction method, which makes pollution-free rapid execution possible in the fields of offshore civil works and waste disposal. Furthermore, the opportunity exists to extract the piles once the useful life of the structure is passed in a reversal of the installation process.Grand Piling refers to this as a sheet piling solution,for example NL-1N,NL-2N,NL-2U,NL-3,NL-3U,NL-5N.Among them are wide-flange steel sheet piles and weldable steel sheet piles, which are recent additions to the lineup.

| Dimensions | Weight | Per meter of wall | |||||

| Types | Thickness | Width | Height | Per pile | Per wall | Modulus of Section | Moment of Inertia |

| mm | mm | mm | Kg/m | Kg/m2 | Cm3/m | Cm4/m | |

| NL-1N | 4 | 250 | 35 | 10.4 | 41.6 | 26.8 | 64 |

| 5 | 250 | 36 | 12.9 | 51.6 | 33.3 | 80.8 | |

| NL-IN | 5 | 245 | 36 | 12.7 | 51.8 | 32.7 | 78.8 |

| NL-2N | 4 | 250 | 36 | 11.8 | 47.2 | 48.6 | 85.1 |

| 5 | 250 | 37 | 14.8 | 59.2 | 59.7 | 107 | |

| NL-2U | 4 | 333 | 50 | 14.2 | 42.6 | 115 | 404 |

| 5 | 333 | 51 | 17.9 | 53.7 | 144 | 510 | |

| NL-3 | 5 | 333 | 74 | 21.6 | 64.8 | 171 | 636 |

| 6 | 333 | 75 | 25.9 | 77.7 | 204 | 762 | |

| NL-3U | 5 | 333 | 85 | 19.3 | 57.9 | 272 | 2000 |

| 6 | 333 | 87 | 23.3 | 69.9 | 330 | 2480 | |

| NL-5N | 5 | 500 | 160 | 33.6 | 67.2 | 452 | 3620 |

| 6 | 500 | 161 | 40.4 | 80.8 | 540 | 4360 | |

| 7 | 500 | 162 | 47.1 | 94.2 | 626 | 5080 | |