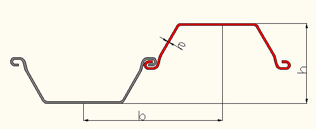

OT sheet piles have been used all the world, especially T 11A,OT12, OT13,OT13A,OT14,OT18.The level of engineering support for a project may range from technical advice on installation equipment, right through to full design reports.The ability of retaining walls to prevent or restrict the passage of ground water is of great importance in many applications e.g. In basements, underground tanks, temporary cofferdams and containment barriers.This pile is made up of two U-type sheet piles welded together to form a box section. The engineering team have diverse qualifications and experience, but are generally focused on civil, structural and geotechnical applications.A sealed sheet pile wall provides a safe, economic solution in any situation where control of groundwater, to minimise the risk of settlement of adjacent property and keeping excavations dry, is an issue. Appropriate combination of sheet piles makes available a variety of section moduli, and, depending upon design requirements, the most suitable and economical type of sheet pile can be selected.

The Engineering Departments in the main centres of China, Malaysia and the UAE are equipped with state of the art analysis software, plus a considerable library of technical publications and international standards. The steel sheet pile, principally of the Larsen type, have been improved in shape to prevent loosening.The water-tightness of sheet pile interlocks almost invariably improves with time but a sealant will provide a means by which the flow/passage of water can be controlled immediately.Having a maximum section modulus of 8,700cm3 per meter of pile wall width, it is suited for use in large quay walls.

Using these, designs can be provided for virtually every application, in accordance with the relevant standards from the region.All construction projects are unique with ground conditions and installation methods varying from site to site; therefore the sealant system adopted must be designed accordingly.Corner sheet pile is a newly developed type produced by rolling to replace the conventional T shape corner sheet pile produced by welding.Chemical composition, mechanical properties, shape and dimensions conform to the requirements of JIS A 5523. Press braking is a discrete process that produces individual piles per process operation.Clutch mechanisms and strengthening plates are then welded to the body of the sheet pile in order to achieve the desired finished product.

For installation, OT20,OT21,OT22,OT23,OT24,OT25, OT26 can be used without modification. Arcelor sheet piles are produced using both cold forming and cold rolling methods. Sealants are available to make driving easier and systems are also available to protect the sealants when driving the piles into gravels and difficult ground.The length of box sheet piles combined can be reduced freely depending upon the design requirements, and this means great economy.

This simple but effective process allows ESC to use the same machinery to produce and almost infinite scope of products suitable for a wide range of end uses.The integrity of a sealant system in use will depend upon it ’s suitability with respect to the method of pile installation adopted and the ground conditions.The cold forming process uses a brake press to bend a flat plate into the required profile..Thus it eliminates the need for welding and other fabrication processes, and is far lighter in weight.

| Section | Width | Height | Thickness | Sectional Area |

Mass | Section Modulus |

Moment of Inertia |

|

| B mm | H mm | tmm | cm2/m | kg/m Single Pile | kg/m2 of Wall | cm3/m | cm4/m | |

| OT Profiles | ||||||||

| OT11A | 600 | 360 | 8.0 | 131.8 | 62.1 | 103.5 | 1160 | 20765 |

| OT12 | 600 | 360 | 8.5 | 140.2 | 66.0 | 110.0 | 1220 | 21978 |

| OT13 | 600 | 360 | 9.0 | 148.3 | 69.9 | 116.4 | 1290 | 23182 |

| OT13A | 600 | 360 | 9.5 | 156.5 | 73.7 | 122.9 | 1360 | 24375 |

| OT14 | 600 | 360 | 10.0 | 164.8 | 77.6 | 129.4 | 1420 | 25559 |

| OT18 | 600 | 485 | 8.0 | 150.3 | 70.8 | 118.0 | 1790 | 43421 |

| OT19 | 600 | 485 | 8.5 | 159.7 | 75.2 | 125.4 | 1890 | 45988 |

| OT20 | 600 | 485 | 9.0 | 169.2 | 79.7 | 132.7 | 2000 | 48537 |

| OT21 | 600 | 485 | 9.5 | 178.5 | 84.1 | 140.1 | 2100 | 51069 |

| OT22 | 600 | 485 | 10.0 | 187.3 | 88.5 | 147.4 | 2200 | 53584 |

| OT23 | 610 | 485 | 10.5 | 200.7 | 96.1 | 157.6 | 2290 | 56098 |

| OT24 | 610 | 485 | 11.0 | 210.3 | 100.7 | 165.1 | 2390 | 58583 |

| OT25 | 610 | 485 | 11.5 | 219.8 | 105.3 | 172.6 | 2490 | 61051 |

| OT26 | 610 | 485 | 12.0 | 229.5 | 109.9 | 180.1 | 2590 | 63503 |