| Section | Dimensions | Mass | Moment of inertia |

Modulus of section |

||||

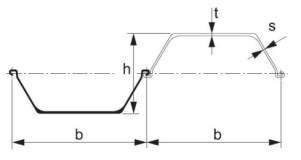

| Width | Height | Thickness | Per pile | Wall | ||||

| b | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m2 | cm4/m | cm3/m | |

| PU 6 | 600 | 226 | 7.5 | 6.4 | 45.6 | 76 | 6780 | 600 |

| PU 7 | 600 | 226 | 8.5 | 7.1 | 49.9 | 83.1 | 7570 | 670 |

| PU 8 | 600 | 280 | 8.0 | 8.0 | 54.5 | 90.9 | 11620 | 830 |

| PU 9 | 600 | 280 | 9.0 | 8.7 | 58.8 | 98.0 | 12830 | 915 |

| PU 11 | 600 | 360 | 8.8 | 8.4 | 61.8 | 103.0 | 19760 | 1095 |

| PU 16 | 600 | 380 | 12.0 | 9.0 | 74.7 | 124.0 | 30400 | 1600 |

| PU 20 | 600 | 430 | 12.4 | 10.0 | 84.3 | 140.5 | 43000 | 2000 |

| PU 25 | 600 | 452 | 14.2 | 10.0 | 93.6 | 156.0 | 56490 | 2500 |

| L2S | 500 | 340 | 12.3 | 9 | 69.7 | 139.4 | 27200 | 1600 |

| L3S | 500 | 400 | 14.1 | 10 | 78.9 | 157.8 | 40010 | 2000 |

| L4S | 500 | 440 | 15.5 | 10 | 86.2 | 172.0 | 55010 | 2500 |

| L5S | 500 | 450 | 20.6 | 11.5 | 106.0 | 212.0 | 72000 | 3200 |

| JSP2 | 400 | 200 | 10.5 | 0 | 48 | 120.0 | 8740 | 874 |

| JSP3 | 400 | 250 | 13.0 | 0 | 60.0 | 150.0 | 16800 | 1340 |

| JSP4 | 400 | 170 | 15.5 | 0 | 76.1 | 190.0 | 38600 | 2270 |

| GU12-500 | 500 | 340 | 9 | 8.5 | 56.6 | 113.2 | 19640 | 1155 |

| GU13-500 | 500 | 340 | 10.0 | 9.0 | 60.8 | 121.7 | 21390 | 1260 |

| GU15-500 | 500 | 340 | 12.0 | 10.0 | 69.3 | 138.6 | 24810 | 1460 |

| PU6R | 600 | 280 | 6.0 | 6.0 | 42.2 | 70.0 | 8940 | 640 |

| PU7R | 600 | 280 | 6.5 | 6.3 | 44.3 | 74.0 | 9580 | 685 |

| PU8R | 600 | 280 | 7.5 | 6.9 | 48.7 | 81.0 | 10830 | 775 |

| PU9R | 600 | 360 | 7.0 | 6.4 | 49.5 | 82.0 | 16930 | 940 |

| PU10R | 600 | 360 | 8.0 | 7.0 | 53.8 | 90.0 | 18960 | 1055 |

| PU11R | 600 | 360 | 9.0 | 7.6 | 58.1 | 97.0 | 20960 | 1165 |

| PU13R | 675 | 400 | 10.0 | 7.4 | 65.6 | 97.0 | 25690 | 1285 |

| PU14R | 675 | 400 | 11.0 | 8.0 | 70.5 | 104.0 | 28000 | 1400 |

| PU15R | 675 | 400 | 12.0 | 8.6 | 75.4 | 112.0 | 30290 | 1515 |

Sheet pile PU6R PU7R PU8R are installed by augering or driving PU9R PU10R into the ground at the desired angle. This option is available only if the Veri- fication PU6R option is selected in the Model window (section 4.1.1).A pneumatic PU7R drifter will drill a 3 to 6 inch diameter rock PU8R socket approximately 10 to 25 feet deep from the PU9R same rig that drove the pipe. When the option PU10R Sheet Piling determined is selected for determining if a load is either favorable or unfavorable, the program first defines the passive side using only the surface levels at both side (the lower side is set to passive).

The holes in rock are cleaned by steel sheet piles PU 6R and PU 7R jet prior to installing tendon PU8R tiebacks. Quick drying nonexpanding PU 9R grout is installed by PU 10R gravity flow. Then the loads situated at the passive side are considered as favorable and the loads at the active side are considered as unfavorable.The PU 7R tiebacks are then prestressed with hydraulic jacks to about 25 percent PU 6R higher than their working stress. This automatic determination can therefore be incorrect in some cases; for example, when the lower side, due to water pressures, PU 8R is actually the active side.The working stress is PU 9R equal to about 50 percent of ultimate strength. That’s why using this option requires some careful.The allowable design load on the prestressed tiebacks PU 10R can be estimated using the bond strength between the rock or soil and the cement grout.