Project Photos

/ KURT Urban Partners, USA

KURT Urban Partners, USA

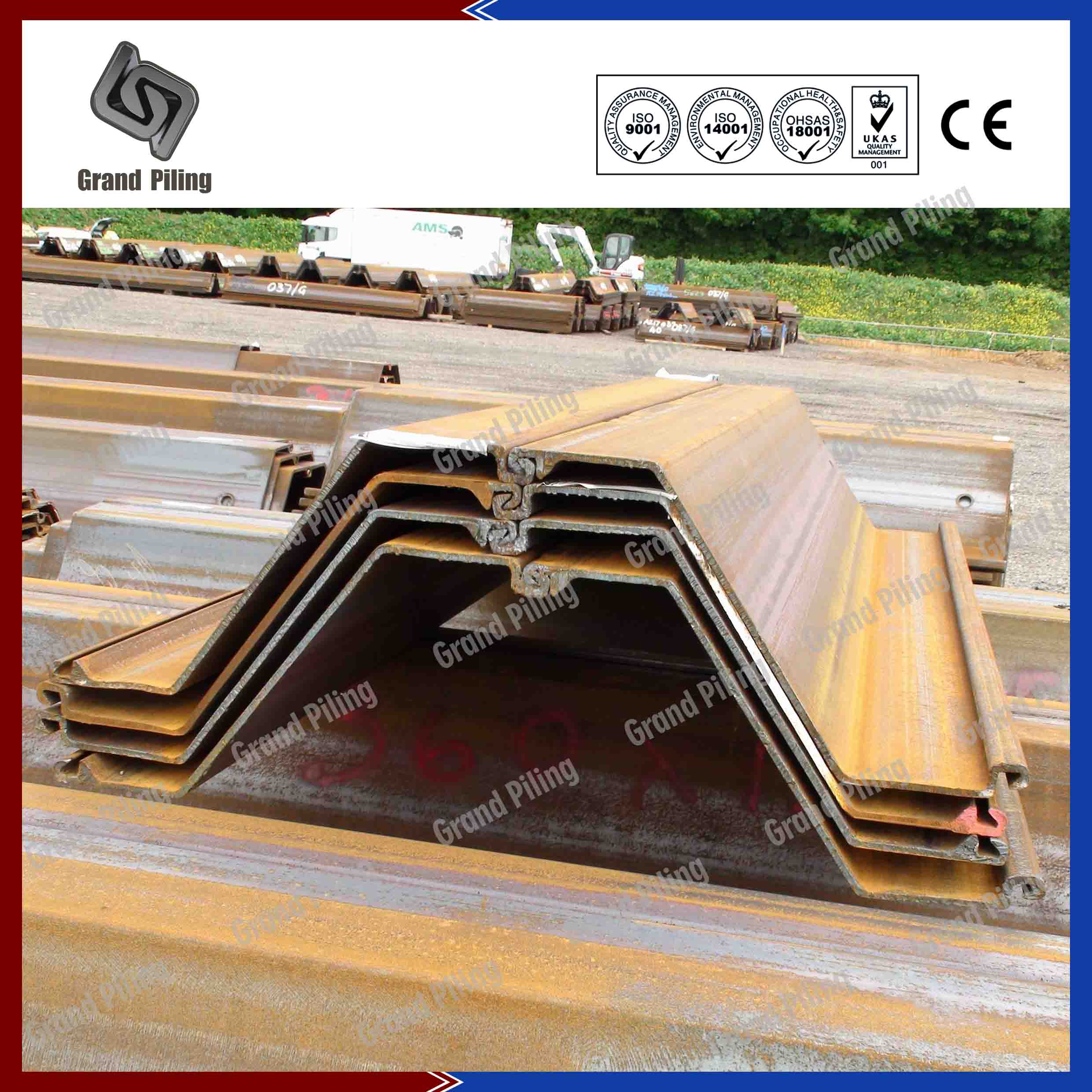

The clients ordered 5500 tons of AZ28-700 sheet piles in various lengths for this projects. Once approval was received the manufacturing was carried out in the piling factory for delivery to the site. As always, our personnel were on site to assist contractors during the beginning of the installation process. Several recommendations were made regarding piling guides and handling processes. Installation was done by pitching the sheet piles in a piling frame and driving to refusal with an ICE 815 vibro hammer. Piles were then driven to the final required level using an IHC S90 hydraulic hammer, together with a pile helmet. We provided efficient Dawson Lifting Shackles that helped increase the productivity of the installation, while ensuring maximum safety during the process. Most of the time, steel sheet piles act as retaining structure for excavation works. They can be installed easily and extracted anytime when the construction work is completed. The steel sheet piles can then be re-used and carried forward for later construction stages.

Previous: Gas Natural, Colombia