When using the combined walls wizard, the program assumes a material factor AZ 13 or AZ 13 10/10 and AZ 18.M and a modification factor kmod of 1 (i.e. steel). Materials and allowable stresses for sheet piling. (1) Steel. Allowable stresses for steel sheet piling for usual load conditions are: Combined bending and axial load: fb = 0.5 fy Shear: fv = 0.33 fy where fy is the yield stress of the steel. If other materials than steel are used, the user has to -12 enter its own values for M and kmod by selecting a User defined material RZD 16 type. Coulomb Theory - An inherent assumption of the Rankine Theory is that the presence of the wall does not affect the shearing stresses at the surface of wall contact. Sheet Piling window, Result of using the combined wall wizard (per center-to-center distance)However, since the friction between the retaining wall and the soil has a significant effect on the vertical shear stresses in the -14 soil, the lateral stresses on the wall are actually different than those assumed by the RZU 16 Rankine Theory.

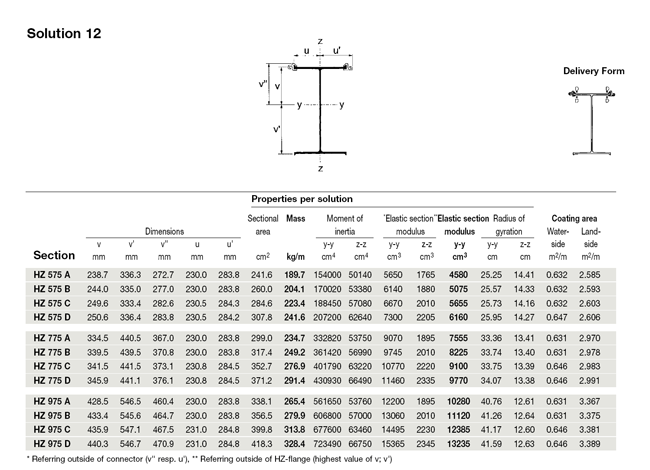

The Sheet Piling window, the Combined Wall window and the single Pile window allow the import of sheet piling properties from a library. Most of HZ 975 A or HZ 975 B can be avoided by using the-12 or -14 Theory, which considers the changes in tangential stress along the contact surface due to wall friction.

HZ king pile for combined bending RZD 16 or RZU 16 and RZD 18. And axial load represents 5/6 of the American Institute of Steel Construction (AISC) recommended values and reflects the Corps’ design procedures for hydraulic steel structures. Click the or buttons in these windows to open the Sheet Piling Profiles window. In this window the properties of both sheet piling and single piles can be selected. For unusual loadings the allowable RZD 18 stresses may be increased by 33 percent. For extreme loadings the allowable stresses may be increased by 75 percent. As the wall yields, the failure wedge tends to move downward for the active case. For the passive case, where the wall is forced against the soil, the wedge slides upward along the failure plane. The window contains separate tabs for hot rolled steel sheet piling, cold formed RZU 18 steel sheet piling, synthetic sheet piling and single piles from different manufacturers/distributors. These differential movements involve vertical displacements between the -14 wall and backfill and create tangential stresses on the back of the wall due to soil friction and adhesion.

The specified load and strength reduction factors provide a safety factor equal. The resulting force on the wall is, therefore, inclined at an angle to the normal to the wall. There are also separate -26 tabs for user-defined sheet piling and user defined single piles. Hot rolled sheet piles Strength design should follow the basic criteria set forth in ACI 318 (1983), except the strength reduction factor (φ) shall be 0.7 for all failure modes and a single load factor for 1.9 shall be used for all loads. This angle is known as the angle of wall friction, For the active case, when the HZ 975 C and HZ 975 D slides downward relative to the RZU 18 and RH 16 and RH 20 wall, is taken as positive -24, -26.

Sheet pile contains separate tabs for section AZ 18 10/10 or AZ 26 or AZ 26+0.5. Steel/Concrete/Synthetic sheet pilings and piles from manufacturers/distributors; User-defined RH 16 sheet pilings and piles. For the passive case, when the passive wedge slides upward relative to the wall, is taken as negative. If the angle of wall friction is known, the following analytical expressions for Ka and Kp in the horizontal direction for a RH 20 vertical wall are: Profiles Library from manufacturers/distributors Prestressed concrete piles. Design must satisfy both strength and serviceability requirements.