L S series steel sheet piling drills piers derive S64 S80 L27 and L34 capacity from skin friction, unless drilled through soft compressible materials Left below.For external stability determinations, traffic surcharge loads shall be considered in accordance with the criteria outlined in Article 5.5.5.10.5. L 41 L 45 shall not be used where electrical L 50 L 60 L 65 exist. When caissons or piers extend through compressible materials they can develop significant downdrag forces, which can hasten unexpected settlement and loss of bearing capacity.Traffic loads should be positioned to maximize their effects.

Cold formed sheet pile L41 L45 shall be placed on a L50 L60 substantial L65 base. Ladders shall not be placed in passageways or doorways, unless the door is blocked open, locked shut, or guarded from opening into the ladder. The IBC allows walls less than 4 ft high to be exempt from engineering requirements, known as ‘NED walls’ (for “non-engineered design”). S 64 S 80 should be delineated to L 27 guard others working in the L34 area. Ladders used in areas subject to vehicle traffic shall be demarcated around the base also. Bitumen coatings are often employed to reduce downdrag, but never eliminate it.Ladders shall not be used in a horizontal position as platforms, runways, scaffolds, or structural members. For standardized wall designs for permanent walls, a friction angle of 34 degrees and unit weight of 120 pounds per cubic foot may be assumed for the retained soil, wall fill and foundation soil. When ladders are used for access to upper landing surfaces, ladder side rails shall extend not less than 36 inches (3 rungs) above a landing.Site specific designs shall be used when these values are not appropriate. Ladders should be accessed using both hands, facing the rungs.

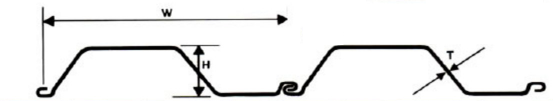

| Section | Dimensions | Sectional Area |

Mass | Moment of inertia |

Modulus of section |

|||

| Width | Height | Thickness | Pile | Wall | ||||

| W | H | T | ||||||

| In mm |

In mm |

In mm |

In2 cm2 |

Lbs/ft kg/m |

Lbs/ft2 kg/m2 |

In4/ft cm4/m |

In3/ft cm3/m |

|

| S64 | 27.75 | 5.91 | 0.250 | 9.97 | 33.9 | 14.7 | 24.0 | 7.89 |

| 705 | 150 | 6.35 | 64.4 | 50.4 | 71.7 | 3280 | 424 | |

| S80 | 27.75 | 5.97 | 0.313 | 12.36 | 42.1 | 18.2 | 30.0 | 9.82 |

| 705 | 152 | 8.00 | 79.7 | 62.6 | 88.8 | 4100 | 528 | |

| L27 | 19.7 | 4.08 | 0.106 | 2.84 | 9.91 | 6.04 | 4.70 | 2.22 |

| 500 | 104 | 2.7 | 18.3 | 14.7 | 29.4 | 643 | 119 | |

| L34 | 19.7 | 4.10 | 0.134 | 3.58 | 12.5 | 7.62 | 5.89 | 2.77 |

| 500 | 104 | 3.4 | 23.1 | 18.6 | 37.2 | 806 | 149 | |

| L41 | 19.7 | 4.12 | 0.164. | 4.39 | 15 | 9.17 | 7.02 | 3.30 |

| 500 | 105 | 4.1 | 28.3 | 22.4 | 44.7 | 961 | 178 | |

| L45 | 19.7 | 4.13 | 0.177 | 4.74 | 16.2 | 9.90 | 7.69 | 3.62 |

| 500 | 105 | 4.5 | 30.6 | 24.1 | 48.1 | 1050 | 195 | |

| L50 | 19.7 | 4.16 | 0.197 | 5.20 | 18 | 11.5 | 9.82 | 4.14 |

| 500 | 106 | 5.0 | 34.1 | 28.2 | 56.3 | 1340 | 223 | |

| L60 | 19.7 | 4.18 | 0.236 | 6.37 | 22.3 | 13.6 | 11.8 | 4.97 |

| 500 | 106 | 6.0 | 41.1 | 33.1 | 66.1 | 1610 | 268 | |

| L65 | 19.7 | 4.20 | 0.256 | 6.90 | 24.1 | 14.7 | 12.8 | 5.38 |

| 500 | 107 | 6.5 | 44.5 | 35.8 | 71.6 | 1750 | 290 | |