Larssen sheet piles models the sheet piling as an elasto-plastic beam on a foundation of uncoupled elasto-plastic springs (representing the soil).The purpose of L600,L600K and L601 is to provide guidance for the safe design and economical construction of sheet pile retaining walls and floodwalls.An anchored sheet pile is said to have free earth support when the depth of embedment is small and pile rotates at its bottom tip. L716,L720 does not prohibit the use of other methods of analysis that maintain the same degree of safety and economy asstructures designed by the methods outlined herein.Thus, there is no point of inflection in the pile.

It is assumed that The base of the L703 pile is relatively free to move, so passive resistance is mobilized on one face only.Stiffness. Uniform or variable values can be used for the elastic bending stiffness and normal stiffness along the beam axis. A library of L602,L603 and L603K is available for quick selection of standard and user-defined sheet piling profiles. References L606,L607 pertaining to this manual are listed in Appendix A. Additional reference materials pertaining to the subject matter addressed in this manual are also included in Appendix A.

It is assumed that The base of the pile is relatively fixed, so that there is a point of contra-flexure above the toe of the pile.The user can introduce normal forces and L603 10/10,L604 and L605 will calculate the additional moments and displacements that follow from the inputted normal force. Passive resistance is mobilized on both faces (similar to cantilever pile).The lateral pressure increases linearly with depth.No wall friction Several computer programs are available to assist in applying some of the analytical functions described in this manual.

A special combined wall wizard calculates the relevant values for walls made from a combination of sheet piling and piles.This manual applies to all HQUSACE elements, major subordinate commands, districts, laboratories, and field operating activities (FOA) having civil works responsibilities.An anchored L602,L603 sheet pile is said to have free earth support when the depth of embedment is large and the bottom tip of the pile is fixed against rotation. Thus, there is change in curvature of pile, hence inflection point occurs. L606, and L607 can determine these yield values from the well-established slip surface theories of Culmann, Kötter or Müller-Breslau.Elasto-Plastic.L604 and L605 can accommodate the soil stiffness for the virgin loading state and the unloading/reloading state.There are types of anchored sheet pile walls 1. Free earth support piles, 2. Fixed earth support piles.Geometrical Non-linear. A compressive normal force will introduce additional bending.D-SHEET PILING derives the initial horizontal stress from the approximate initial vertical stress using Jáky’s equation for the lateral stress ratio K0. Performs soil-structure interaction analysis of cantilever or anchored walls (Dawkins 1992). L600,L600K and L601 calculates additional stresses due to surcharge or a non-horizontal ground surface based on Boussinesq’s stress distribution theory.Free earth support piles The lateral pressure increases linearly with depth. Wall friction is negligible.L703,L716 and L720 makes use of multi-linear relationships between horizontal stress and displacement, with different values for active and passive yielding.Initial Stress.

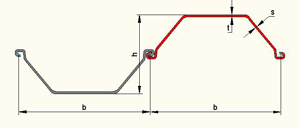

Sheet piling performs many of the classical design and analysis techniques for determining required depth of penetration and/or factor of safety and includes application of Rowe’s Moment Reduction for anchored walls. (CORPS Program X0031)Anchors. L603K,L603 10/10 Anchors are characterized by arbitrary direction, elastic normal stiffness, zero pressure condition and limited capacity due to yielding or soil resistance (Figure 1.2). Pre-tensioning of anchors is optional.

| Section | Dimensions | Mass | Moment of inertia | Modulus of section | ||||

| Width | Height | Thickness | Per pile | Wall | ||||

| b | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m2 | cm4/m | cm3/m | |

| L600 | 600 | 150 | 9.5 | 9.5 | 56.4 | 94 | 3825 | 510 |

| L600K | 600 | 150 | 10 | 10 | 59.4 | 99 | 4050 | 540 |

| L601 | 600 | 310 | 7.5 | 6.4 | 46.8 | 78 | 11520 | 745 |

| L602 | 600 | 310 | 8.2 | 8 | 53.4 | 89 | 12870 | 830 |

| L603 | 600 | 310 | 9.7 | 8.2 | 64.8 | 108 | 18600 | 1200 |

| L603K | 600 | 310 | 10 | 9 | 68.1 | 113.5 | 19220 | 1240 |

| L603 10/10 | 600 | 310 | 10 | 10 | 69.6 | 116 | 19530 | 1260 |

| L604 | 600 | 380 | 10 | 9 | 73.8 | 123 | 30400 | 1600 |

| L605 | 600 | 420 | 13 | 9.2 | 85.5 | 142.5 | 43890 | 2090 |

| L606 | 600 | 435 | 14.4 | 9.2 | 94.2 | 157 | 54375 | 2500 |

| L607 | 600 | 452 | 19 | 10.6 | 114 | 190 | 72320 | 3200 |

| L703 | 700 | 400 | 9.5 | 8 | 67.5 | 96.4 | 24200 | 1210 |

| L716 | 700 | 440 | 10.2 | 9.5 | 79.9 | 114.2 | 35200 | 1600 |

| L720 | 750 | 450 | 12 | 10 | 96.4 | 128.5 | 45000 | 2000 |