The origin of: steel sheet piles dates back more than one hundred years.It has been shown by performance testing the various sealant products that best results are obtained by thoroughly preparing the interlocks prior to the application of the sealant. Ale Piling offer the design, supply, installation and extraction of Steel Sheet Piles, Plastic Sheet Piles, Tubular Piles, Timber Piles, King Post Walls, Cofferdams, Retaining walls and much more.

OZ26,OZ27,OZ28Afirst took shape as a straight web section. Not only is it difficult to clean and prepare the interlocks to the required standard on the construction site but weather conditions, temperature and humidity or the presence of surface moisture may be detrimental to the bond between the sealant and the steel.

OZ29A,OZ31A,OZ32,OZ33 are used for cellular membrane gravity structures. This and the continuous web development have a positive influence on the calculation of the section modulus, in addition to the following benefits:We always maintain a stock of new and used steel sheet piles, and also have a large selection of plant and equipment available for hire, including piling rigs, floating pontoons and tugs! Once they have cured, most sealant products are inert and therefore a non-hazard but handling the constituents requires care as this operation introduces the possibility of exposure to potentially hazardous substances and may involve working with hot fluids.

Over time, OZ34A,OZ36,OZ37,OZ38A,OZ40 evolved into corrugated profiles, transitioning the essential pile characteristics from tension to a bending element. By applying sealants in the workshop, rather than on a construction site, the handling of these materials can be controlled by stringent safety standards. Please view our case studies page, where you will be able to see just a small selection of our previous work in flood defence, sea defence, rail and various temporary works.

Thus the sheet piling was born for retaining wall applications.As the U-Pile concerns were discussed amongst industry experts, the steel mills strived to improve the sheet pile product market. The work is confined to experienced personnel operating in a controlled environment and

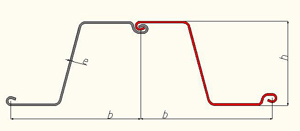

third parties are not subjected to unnecessary risk.The essential changes of the OZ26,OZ27,OZ28A,OZ29A,OZ31A,OZ32 are in the transition of the interlocks and the continuous form of the web. By moving the interlocks symmetrically on both sides of the neutral axis, the rotational issues of its’ U-Pile predecessor were addressed. As a specialist marine and land, sheet piling and earth support contractor, we work with projects both small and big. Interlock preparation to new piles will ensure good adhesion of the sealant to the steel, reducing the risk of damage when driving the piles and loss of performance in service.Thus, the next generation Z-Pile was born. This has the effect of removing any mill scale or other deleterious materials from the interlock and producing a steel surface that the sealant can properly adhere to OZ33,OZ34A,OZ36,OZ37,OZ38A,OZ40.

| Section | Width | Height | Thickness | Sectional Area |

Mass | Section Modulus |

Moment of Inertia |

|

| B mm | H mm | T mm | cm2/m | kg/m Single Pile |

kg/m2 of Wall |

cm3/m | cm4/m | |

| 0Z Sections | ||||||||

| OZ26 | 675 | 429 | 10.5 | 181.0 | 95.9 | 142.1 | 2620 | 57410 |

| OZ27 | 675 | 429 | 11.0 | 188.3 | 99.8 | 147.9 | 2730 | 60043 |

| OZ28A | 675 | 429 | 11.5 | 197.0 | 104.4 | 154.6 | 2850 | 62667 |

| OZ29A | 675 | 429 | 12.0 | 205.5 | 108.9 | 161.3 | 2960 | 65281 |

| OZ31A | 675 | 429 | 12.7 | 217.5 | 115.2 | 170.7 | 3120 | 68927 |

| OZ32 | 675 | 476 | 11.0 | 204.4 | 108.3 | 160.5 | 3180 | 77367 |

| OZ33 | 675 | 476 | 11.5 | 213.3 | 113.1 | 167.5 | 3320 | 80750 |

| OZ34A | 675 | 476 | 12.0 | 222.4 | 117.8 | 174.6 | 3450 | 84121 |

| OZ36 | 675 | 476 | 12.5 | 231.3 | 122.5 | 181.5 | 3580 | 87473 |

| OZ37 | 675 | 476 | 13.0 | 240.1 | 127.3 | 188.5 | 3720 | 90830 |

| OZ38A | 675 | 476 | 13.5 | 249.0 | 132.0 | 195.5 | 3850 | 94167 |

| OZ40 | 675 | 476 | 14.0 | 257.9 | 136.6 | 202.4 | 3980 | 97493 |