Quality assurance systems based on the requirements of SANS ISO 9001: 2000 are in operation.UE channel steel can be used for a wide range of structural elements, from lightweight purlins to columns and beams for industrial and multi-storey structures and bridges.When choosing a rust prevention method for a Russian Channel with taper flange or structure many technical factors including the environment, stress during transport, storage, fitting or erection must be considered.Adequate preparation of the substrate is of vital importance to the ultimate success of the coating, as is the method of application.

The above-mentioned structural steel grades may be welded using any of the standard metal arc and resistance welding processes, usually without any special precautions. The Russian Channels with taper flanges listed may be ordered to conform to the mechanical requirements of any of the international specifications listed.Paint, hot-dip galvanizing or duplex coatings (zinc plus paint) can be specified for corrosion protection, depending on the aggressiveness of the environment.Choice of the protective taper flanges channel is considered to be the responsibility of the specifier, fabricator or end user.

However, when welding taper flanges channels, BS 5135: 1984 "Metal-arc welding of carbon and carbon manganese steels" should be consulted to determine preheat requirements at low heat inputs. Other sections, lengths, grades and tolerances may be available on inquirer.Larger surface defects may be removed, providing the nominal thickness is not reduced by more than 7%.Surface defects up to a maximum depth of 3% of the nominal thickness shall not be considered as a reason

for UE steel channel .

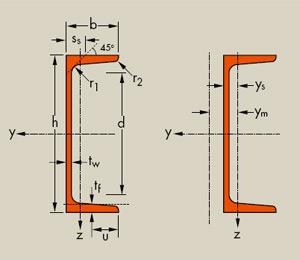

Dimensions:

GOST 8240-47

PN-H-93451

Tolerances:

GOST 8240-47

EN 10279: 2000

Surface condition:

According to EN 10163-3: 2004, class C, subclass 1

| Size | Nominal dimensions | Cross section |

Nominal weight 1m |

Section properties, static data | ||||||||

| No more than |

X-X | |||||||||||

| h | b | s | t | R | r | A | G | Ix | Wx | ix | Sx | |

| mm | cm2 | kg/m | c4 | cm3 | cm | cm3 | ||||||

| Nr. 5 | 50 | 32 | 4,4 | 7,0 | 6,0 | 2,5 | 6,16 | 4,84 | 22,8 | 9,1 | 1,92 | 5,59 |

| Nr. 6,5 | 65 | 36 | 4,4 | 7,2 | 6,0 | 2,5 | 7,51 | 5,90 | 48,6 | 15,0 | 2,54 | 9,00 |

| Nr. 8 (UE 80) | 80 | 40 | 4,5 | 7,4 | 6,5 | 2,5 | 8,98 | 7,05 | 89,4 | 22,4 | 3,16 | 23,30 |

| Nr. 10 (UE100) | 100 | 46 | 4,5 | 7,6 | 7,0 | 3,0 | 10,90 | 8,59 | 174,0 | 34,8 | 3,99 | 20,40 |

| Nr. 12 (UE120) | 120 | 52 | 4,8 | 7,8 | 7,5 | 3,0 | 13,30 | 10,40 | 304,0 | 50,6 | 4,78 | 29,60 |

| Nr. 14 (UE140) | 140 | 58 | 4,9 | 8,1 | 8,0 | 3,0 | 15,60 | 12,30 | 491,0 | 70,2 | 5,60 | 40,80 |

| Nr. 16 (UE160) | 160 | 64 | 5,0 | 8,4 | 8,5 | 3,5 | 18,10 | 14,20 | 747,0 | 93,4 | 6,42 | 54,10 |

| Nr. 16a | 160 | 68 | 5,0 | 9,0 | 8,5 | 3,5 | 19,50 | 15,30 | 823,0 | 103,0 | 6,49 | 59,40 |

| Nr. 18 (UE180) | 180 | 70 | 5,1 | 8,7 | 9,0 | 3,5 | 20,70 | 16,30 | 1090,0 | 121,0 | 7,24 | 69,80 |

| Nr. 18a | 180 | 74 | 5,1 | 9,3 | 9,0 | 3,5 | 22,20 | 17,40 | 1190,0 | 132,0 | 7,32 | 76,10 |

| Nr. 20 (UE200) | 200 | 76 | 5,2 | 9,0 | 9,5 | 4,0 | 23,40 | 18,40 | 1520,0 | 152,0 | 8,07 | 87,80 |

| Nr. 22 | 220 | 82 | 5,4 | 9,5 | 10,0 | 4,0 | 26,70 | 21,00 | 2110,0 | 192,0 | 8,89 | 110,00 |

| Nr. 24 | 240 | 90 | 5,6 | 10,0 | 10,5 | 4,0 | 30,60 | 24,00 | 2900,0 | 242,0 | 9,73 | 139,00 |

| Nr. 27 | 270 | 95 | 6,0 | 10,5 | 11,0 | 4,5 | 35,20 | 27,70 | 4160,0 | 308,0 | 10,90 | 178,00 |

| Nr. 30 | 300 | 100 | 6,5 | 11,0 | 12,0 | 5,0 | 40,50 | 31,80 | 5810,0 | 387,0 | 12,00 | 224,00 |

| Nr. 33 | 330 | 105 | 7,0 | 11,7 | 13,0 | 5,0 | 46,50 | 36,50 | 7980,0 | 484,0 | 13,10 | 281,00 |

| Nr. 36 | 360 | 110 | 7,5 | 12,6 | 14,0 | 6,0 | 53,40 | 41,90 | 10820,0 | 601,0 | 14,20 | 350,00 |

| Nr. 40 | 400 | 115 | 8,0 | 13,5 | 15,0 | 6,0 | 61,50 | 48,30 | 15220,0 | 761,0 | 15,70 | 444,00 |