379. Sheet Piling Constructions

We supply and installs vibratory-driven sheet piling for both permanent structures and temporary retaining walls or construction pits.

378. Sheet Pile System

Depending on site conditions and the construction project, builders have a choice of using overlapping or interlocking sheet pile systems.

377. Cost Effective Of Sheet Piles

Sheet piles are usually the most cost effective deep foundation solution.

376. Sheet pile installation techniques

Vibration is the most commonly used technique for installing and extracting sheet pile through the use of a vibratory hammer.

375. Sheet Piling Cofferdams

The bracing system consists of horizontal members called wales, which transfer loads from the sheet piling to compres- sion members called struts, or to external supports called tie backs or anchors.

374. Methods to Reduce Oblique Bending in a Sheet Piling Wall

As a result of oblique bending, the strength and lateral stiffness of the sheet piling wall may be decreased considerably up to values of 60 % to 70 % compared to a continuous sheet piling wall.

373. Sheet Pile Formwork System

The only purpose made sheet pile capping system available for concrete cap formwork, is faster and more cost effective than any on-site "lash ups".

372. What is the difference between Hot Rolled and Cold Formed Sheet Piling?

Hot Rolled Sheet Piling are produced directly in hot form from a beam blank into its final shape.

371. Basement Construction & Sheet Piles Retaining Walls

Sheet piles retaining walls are a very cost effective way of forming a retaining wall, as there is reduced bulk excavation with maximum underground space.

370. Sheet Piling Infills

Sheet Piling Infills are designed as a quick, economical and lightweight solution to infilling the open pans in an exposed sheet piling wall.

369. Sheet pile wall cappings

Permanent sheet pile wall structures are finished off at the top with a steel capping or reinforced concrete capping beam.

368. Braced sheet piling walls with ground anchors

The bracing of sheet piling walls using ground anchors facilitates deep excavations whilst leaving the area free of obstacles.

367. Performance of Sheet Pile Wall in Peat

To study the performance of sheet pile wall in peat during roadway construction, a long-term instrumentation program was conducted over a period of two years, measuring total lateral earth pressures, sheet pile deflections, soil movements, and water table level variances during construction.

366. Fiberglass Sheet Piles Advantages

There are three types of composite sheet piles, light piles, heavy duty sheet piles and super heavy duty piles.

365. Pultruded Fiberglass Sheet Piling

Pultruded sheet piling is a section of piling that is manufactured by the continuous processing of raw materials by pulling resin-rich reinforcements through a heated steel die to form profiles of constant cross section of continuous length.

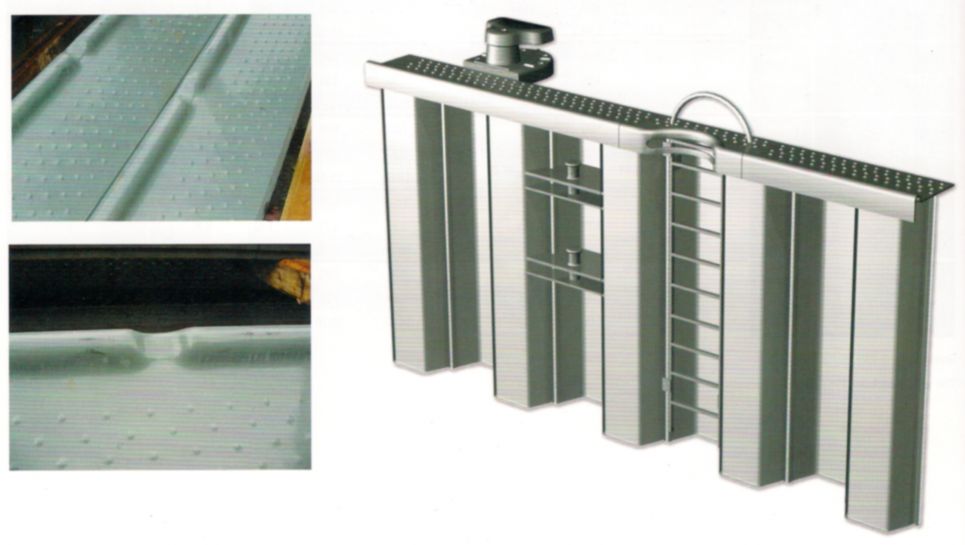

364. Overlap sheet pile

Our heavy-duty overlap sheet pile is designed for shoring and bulkheading.

363. Sheet Piling and Cofferdams

Temporary sheet piling shall have a minimum nominal section modulus of 18.1 in3/ft of wall,when retaining traffic loads or adjacent to traffic.

362. Sheet piling wall comparision

In addition to economy, sheet piling offers a readily available, environmentally-friendly solution for retaining structures, providing excellent stability and ease of construction in both permanent an temporary applications.

361. Sheet Pile For Sale

Sheet pile is used to retain soil or water using steel sheet connectors with interlocking edges that form a wall and can either be permanent or temporary.