11. Warri Port Land Relamation Nigeria. 2009-2010

Project Details: 3200 tons of GPU32. all in 18m. The existing seabed was between approximately -2.0 EL to +1.0 EL in the vicinity of the proposed wall. Subsequent filling activity has reclaimed the area to approximately +3.0 EL. Fill material is dense to very dense sandy gravel with cobbles and boulders.Installation was done by pitching the sheet piles in a piling frame and driving to refusal with an ICE 815 vibro hammer. Piles were then driven to the final required level using an IHC S90 hydraulic hammer, together with a pile helmet

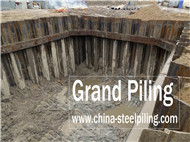

12. DBE Batallion, Al Kizaiza / Basrah Iraq. 2008

Project Details: GPU32 3500 tons .From the beginning,Grand Steel Piling started to designe the retaining wall .The remedy consisted of an 18 metre sheet pile retaining wall driven using a pileleader and supported by universal beam struts that raked up off existing pilecap structures. Due to the collapse, the soil/Sand contained large quantities of construction debris, including concrete blocks and remnant anchor cables from the failed wall. The sheet piles were required to punch through all obstacles in order to reach penetration depth. Using a high frequency hydraulic vibro hammer together with a unique hardened knife edge attached to the reinforced pile tip, the pile penetrated every kind of debris to achieve the required depth, with no declutching experienced. All sheet piles were fabricated on site using I Beam beds. Construction of the basement pile caps and subsequent structure was then able to proceed unhindered.

13. Fourth Transmission Pipeline project FTP PTT,Laem Chaband,Thailand . 2010

Project Details: 1200 tons of GPU19 sheet piling used standard container length. all shipped to LAEM CHABANG port . S355 good steel grade. In excess of 1000 no. 12.0m long sheet piles have been installed. Only a proportion of the total sheet pile requirement was supplied to site, and re-use of sheet piles on different structures was an important consideration to minimise costs. Therefore, the best and most economical use of the sheet piles was dependent upon careful planning.

14. Transnordestina Railroad superstructure,Brazil . 2011

Project Details: Grand Piling supplied approximately 600Ton (480Ton Temp and 120Ton Sacrificial) steel sheet piles to form various temporary earth retaining cofferdams and temporary retaining walls. The 9No.cofferdams facilitated the excavation and construction of the proposed spring pad bases, pile caps and bridge abutments whilst the temporary retaining walls were designed to an Highways Agency " Approval In Principle" to form the temporary road diversion. Sheet Piles ranged from 7.0m-14.0m in length retaining up to a maximum of 4.10m.

15. Continous Barge Ujnloading NPLCT at Palau Laut Kota Baru South of Kalimantan Indonisiia. 2011

Project Details: 1520 tons of GPU32. U type sheet piling. All length in 25m. The contract come to China and visited Grand Piling seeral times,Since the port of discharge, is a small port,not so many break vessels for sheet piles going there,Grand Piling work closely with shipping company,and finally find the correct vessels.

16. Troms harbour, Norway . 2009

Project Details: 2930 tons The total length is around 3 km long. A GPU25 650X540X10 wall was choosen because Grand Piling could guarantee to deliver the accessories and sheet piles in a very short timeframe. In less than three months, 2930 tonnes of sheet pile up to 24.6 m long, were delivered to the main contractor . The installation works are done from five jack-up platforms with hydraulic hammers.This job was got by Grand Piling's Norway agent.This is the biggest order Grand Steel Piling has done in North Europe,and won Grand Steel Piling a good reputation

17. Poole Twin Sails Bridge; Location :Poole, Dorset,UK.. 2010

Project Details: 2510 tons of GPZ21 685x402x10 Length varying from 11.5m to 20m. supplied in welded pairs. slinging holes. All steel sheet piles were used to form a river frontage retaining structure and 3 no. temporary earth retaining cofferdams The temporary sheet pile cofferdams facilitated the excavation and construction of the proposed Bridge.The cofferdams were designed such that any temporary propping could be removed when the base elements had been cast, thereby leaving an unhindered working area for the follow-on

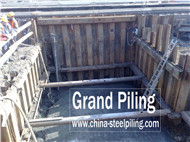

18. Negros Occidental,Philipines. 2008

Project Details: Client was City Goernment of Sagay,the buyer Land Bank of Philippines.Original design was Nippon Steel's type II and Type III sheet piles. Grand Piling's engineers recommend GPU14-600,due to the good price and client service,Grand Piling beated Nippon Steel and get this order 850 tons at 11.8m SY390 steel grade.Now the client already become one of Grand Piling's old friends in Philipines.

19. Eastern Mangroves Project in Abu Dhabi, UAE. 2009

Project Details: 2600 tons of GPU 14 The top soil consist of 4 m thick clayey silt with poor bearing capacity overlying two sand layers interrupted by clayey peat at -15 to -20 m. Sand was placed over the inclined top soil to create a horizontal planum.GPU14 sheet piles were installed as temporary soil retaining wall enabling land-based installation of the heavy steel piles forming the harbour walls. A vibratory hammer based on a jack-up barge was used to drive the 18 m long piles a couple of metres off the location of the permanent wall. Sand was also placed behind the temporary sheet piles installed in front of the planned waiting and mooring areas. Sand was piled up with ships and lorries to EL. +2.5 m. A stone-secured embankment permitted the reduction of soil pressure on the temporary cantilever GPU14 sheet pile wall. A vertical drainage system was installed to increase the bearing capacity of the soil, thus reducing the risks of later settlements.

20. Dhamra Project,India. 2010

Project Details: The original design was Arcelor Mittal's AU25. finally clients choose Grand Piling's GPU25-650 S430 steel grade .length vary The whole project was implemented by a local contractor with the help of an experienced pile driving crew. Additional technical support was provided during the design stage and execution phase by the sheet pile manufacturer's technical department.India has been the second largest market for Grand Piling,only after its native market,China.