AU sheet piling proposed for the Main Wall was a custom designed pile specifically suited to this project. AU14, AU16, AU18, AU20, AU23, AU25 types sheet piles are all from Acelor. Full calculations of the derivation of section modulus for thecustom pile, and the standard pile were supplied to the Client and their Engineers. Backfill in the anchor zone should be compacted to achieve the desired resistance. Near the wall, however, the material should be sufficient porous to allow adequate drainage. Table 3 shows the segment of the GU sheet piles prior to corrosion loss.

The PU sheet pile was built in a modular style which allows the thickness of the plate to be varied to accommodate different stress levels and corrosion zones. The following table gives the approximate minimum diameters of circular cofferdam which can be constructed using various sheet pile sections. Drain holes should be tapped on the wall with adequate frequency.PU12,PU12 10/10, PU18, PU22, PU28, PU32 sheet piles are normally for HZ and OZ steel sheet pile.

For seawall of inadequate elevation, it is advisable to install a drain field using pebbles or gravel field. The diameters are only intended to be for guidance as the actual interlock deviation achieved will be a function of the pile length, the pile section, the penetration required. Table 3 shows the section modulus and moment capacity of each segment of the GU sheet piles prior to corrosion loss. All calculations were performed in accordance with the guidelines set out in BS 5950 Part 5. Smaller diameters can be achieved by introducing bent corner piles, but

larger diameters will result if pairs of piles that have been crimped or welded are used.

GU6N, GU8N,GU16N,GU18N,GU16-400, GU18-400 types are better than sheet piling Thyssen and Thyssenkrupp.

A hard surface made of reinforced concrete also could prove to be effective against erosion caused by overtopping. It can be driven to form a complete circle without the need for corner piles. AZ piles have a maximum angle of deviation of 5°. Such hard surface must be constructed on adequate and well-drained foundation to be effective.

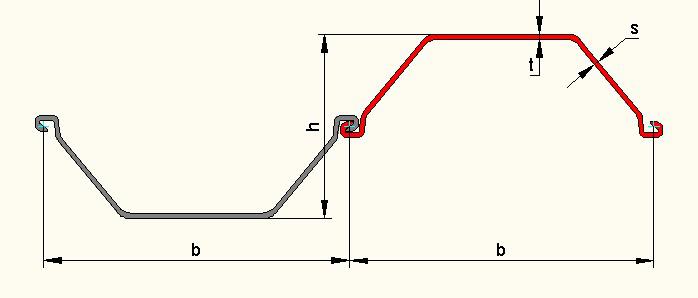

| Section | Dimensions | Mass | Moment of inertia | Modulus of section | ||||

| Width | Height | Thickness | Per pile | Wall | ||||

| b | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m2 | cm4/m | cm3/m | |

| AU | ||||||||

| AU14 | 750 | 408 | 10 | 8.3 | 77.9 | 103.8 | 28710 | 1410 |

| AU 16 | 750 | 411 | 11.5 | 9.3 | 86.3 | 115 | 32850 | 1600 |

| AU 18 | 750 | 441 | 10.5 | 9.1 | 88.5 | 118 | 39300 | 1780 |

| AU 20 | 750 | 444 | 12 | 10 | 96.9 | 129.2 | 44440 | 2000 |

| AU 23 | 750 | 447 | 13 | 9.5 | 102.1 | 136.1 | 50700 | 2270 |

| AU 25 | 750 | 450 | 14.5 | 10.2 | 110.4 | 147.2 | 56240 | 2500 |

| PU | ||||||||

| PU 12 | 600 | 360 | 9.8 | 9 | 66.1 | 110.1 | 21600 | 1200 |

| PU1210/10 | 600 | 360 | 10 | 10 | 69.6 | 116 | 22580 | 1255 |

| PU 18 | 600 | 430 | 11.2 | 9 | 76.9 | 128.2 | 38650 | 1800 |

| PU 22 | 600 | 450 | 12.1 | 9.5 | 86.1 | 143.6 | 49460 | 2200 |

| PU 28 | 600 | 454 | 15.2 | 10.1 | 101.8 | 169.6 | 64460 | 2840 |

| PU 32 | 600 | 452 | 19.5 | 11 | 114.1 | 190.2 | 72320 | 3200 |

| GU | ||||||||

| G6N | 600 | 309 | 6 | 6 | 41.9 | 69.9 | 9670 | 625 |

| GU7N | 600 | 310 | 6.5 | 6.4 | 44.1 | 73.5 | 10450 | 675 |

| GU7S | 600 | 311 | 7.2 | 6.9 | 46.3 | 77.1 | 11540 | 740 |

| GU8N | 600 | 312 | 7.5 | 7.1 | 48.5 | 80.9 | 12010 | 770 |

| GU8S | 600 | 313 | 8 | 7.5 | 50.8 | 84.6 | 12800 | 820 |

| GU13N | 600 | 418 | 9 | 7.4 | 59.9 | 99.8 | 26590 | 1270 |

| GU14N | 600 | 420 | 10 | 8 | 64.3 | 107.1 | 29410 | 1400 |

| GU15N | 600 | 422 | 11 | 8.6 | 68.7 | 114.5 | 32260 | 1530 |

| GU16N | 600 | 430 | 10.2 | 8.4 | 72.6 | 121 | 35950 | 1670 |

| GU18N | 600 | 430 | 11.2 | 9 | 76.9 | 128.2 | 38650 | 1800 |

| GU20N | 600 | 430 | 12.2 | 9.5 | 81.1 | 135.2 | 41320 | 1920 |

| GU21N | 600 | 450 | 11.1 | 9 | 81.9 | 136.5 | 46380 | 2060 |

| GU22N | 600 | 450 | 12.1 | 9.5 | 86.1 | 143.6 | 49460 | 2200 |

| GU23N | 600 | 450 | 13.1 | 10 | 90.4 | 150.7 | 52510 | 2335 |

| GU16-400 | 400 | 290 | 12.7 | 9.4 | 62 | 154.9 | 22580 | 1560 |

| GU18-400 | 400 | 292 | 15 | 9.7 | 69.3 | 173.3 | 26090 | 1785 |