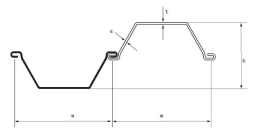

| Section | Dimensions | Section area | Mass | Moment of inertia |

Modulus of section |

|||

|

|

Width | Height | Thickness | Pile | Wall | |||

|

|

w | h | t/s | |||||

|

|

mm | mm | mm | cm2/m | kg/m | kg/m2 | cm4/m | cm3/m |

| MMU5-1 | 600 | 150 | 9.5 | 119.75 | 56.4 | 94 | 3825 | 510 |

| MMU5-2 | 600 | 150 | 10 | 126.11 | 59.4 | 99 | 4050 | 540 |

| MMU6-1 | 600 | 280 | 6 | 89.6 | 42.2 | 70.33 | 8960 | 640 |

| MMU7-1 | 600 | 300 | 6 | 93.42 | 44 | 73.33 | 10350 | 690 |

| MMU7-2 | 600 | 340 | 6 | 98.09 | 46.2 | 77 | 12665 | 745 |

| MMU7-3 | 600 | 360 | 6 | 99.58 | 46.9 | 78.17 | 13320 | 740 |

| MMU8-1 | 600 | 340 | 6.5 | 103.34 | 48.7 | 81.17 | 13260 | 780 |

| MMU8-2 | 600 | 325 | 7 | 109.98 | 51.8 | 86.33 | 13406 | 825 |

| MMU8-3 | 600 | 355 | 7 | 113 | 53.4 | 89 | 14821 | 835 |

| MMU8-4 | 750 | 320 | 6 | 87.1 | 51.3 | 68.4 | 13200 | 825 |

| MMU9-1 | 600 | 360 | 6.5 | 105 | 49.5 | 82.5 | 16920 | 940 |

| MMU9-2 | 600 | 330 | 7.5 | 120.6 | 56.8 | 94.7 | 15097 | 915 |

| MMU9-3 | 750 | 320 | 7 | 101.74 | 59.9 | 79.9 | 15120 | 945 |

| MMU10-1 | 600 | 370 | 7 | 114.44 | 53.9 | 89.8 | 19610 | 1060 |

| MMU11-1 | 600 | 380 | 7.5 | 123.35 | 58.1 | 96.8 | 22230 | 1170 |

| MMU11-2 | 600 | 360 | 8 | 131.6 | 62 | 103.3 | 19980 | 1110 |

| MMU12-1 | 600 | 380 | 8.5 | 140.3 | 66.1 | 110.17 | 22800 | 1200 |

| MMU12-2 | 600 | 310 | 9 | 137.6 | 64.8 | 108 | 18600 | 1200 |

| MMU12-3 | 600 | 310 | 9.5 | 144.6 | 68.1 | 113.5 | 19220 | 1240 |

| MMU12-4 | 500 | 360 | 8 | 144 | 56.5 | 113 | 20790 | 1155 |

| MMU12-5 | 700 | 440 | 7.5 | 123 | 67.6 | 96.57 | 26620 | 1210 |

| MMU12-6 | 600 | 360 | 9 | 148.6 | 70 | 116.7 | 22248 | 1236 |

| MMU12-7 | 450 | 360 | 10 | 184 | 65 | 144.4 | 22482 | 1249 |

| MMU13-1 | 675 | 420 | 7.5 | 124 | 65.6 | 97 | 27090 | 1290 |

| MMU13-2 | 600 | 310 | 10 | 152.9 | 72 | 120 | 19530 | 1260 |

| MMU13-3 | 500 | 355 | 9 | 154.6 | 60.7 | 121.4 | 22454 | 1265 |

| MMU13-4 | 700 | 440 | 8 | 131.2 | 72.1 | 103 | 28600 | 1300 |

| MMU13-5 | 700 | 400 | 10 | 159.8 | 87.8 | 125.4 | 26800 | 1340 |

| MMU13-6 | 500 | 340 | 10 | 167.9 | 65.9 | 131.8 | 22100 | 1300 |

| MMU13-7 | 600 | 360 | 10 | 163.5 | 77 | 128.3 | 22590 | 1255 |

| MMU13-8 | 575 | 360 | 10 | 165.9 | 74.9 | 130.3 | 24225 | 1347 |

| MMU14-1 | 750 | 445 | 8 | 132 | 77.8 | 103.7 | 31372 | 1410 |

| MMU14-2 | 675 | 435 | 8 | 133.2 | 70.6 | 104.5 | 30559 | 1405 |

| MMU15-1 | 675 | 420 | 8.5 | 142 | 75.3 | 112 | 31920 | 1250 |

| MMU15-2 | 500 | 360 | 10 | 176.6 | 69.3 | 138.6 | 26280 | 1460 |

| MMU16-1 | 750 | 440 | 9 | 146.4 | 86.2 | 115 | 35310 | 1605 |

| MMU16-2 | 400 | 290 | 11.5 | 203.8 | 64 | 160 | 22693 | 1565 |

| MMU16-3 | 600 | 380 | 9.5 | 156.7 | 73.8 | 123 | 30400 | 1600 |

| MMU16-4 | 700 | 450 | 9 | 151 | 83 | 118.6 | 36000 | 1600 |

| MMU16-5 | 650 | 480 | 8 | 142.68 | 72.8 | 112 | 39120 | 1630 |

| MMU17-1 | 750 | 430 | 9.5 | 151 | 89.1 | 119 | 35902 | 1670 |

| MMU17-2 | 500 | 420 | 12 | 224 | 88 | 176 | 34860 | 1660 |

| MMU17-3 | 650 | 480 | 8 | 140 | 71.5 | 110 | 29840 | 1660 |

| MMU17-4 | 600 | 440 | 8.5 | 154 | 72.5 | 121 | 36850 | 1675 |

| MMU18-1 | 750 | 460 | 9 | 150.3 | 88.5 | 118 | 40940 | 1780 |

| MMU18-2 | 400 | 310 | 12 | 220.7 | 69.3 | 173.25 | 27668 | 1785 |

| MMU18-3 | 600 | 430 | 9.5 | 165.4 | 77.9 | 129.8 | 38700 | 1800 |

| MMU20-1 | 750 | 460 | 10 | 164.4 | 96.8 | 129 | 46115 | 2005 |

| MMU20-2 | 600 | 440 | 10 | 177 | 83.5 | 139 | 44440 | 2020 |

| MMU20-3 | 600 | 450 | 10.5 | 185 | 87.5 | 145.8 | 45675 | 2030 |

| MMU20-4 | 500 | 450 | 10 | 197.5 | 77.5 | 155 | 45000 | 2000 |

| MMU20-5 | 750 | 480 | 10 | 167.3 | 98.5 | 131.3 | 49440 | 2060 |

| MMU20-6 | 650 | 540 | 8 | 150.1 | 76.6 | 117.8 | 56025 | 2075 |

| MMU21-1 | 750 | 480 | 10 | 169.3 | 99.7 | 133 | 49920 | 2080 |

| MMU21-2 | 600 | 480 | 9.5 | 173.9 | 81.9 | 136.5 | 49440 | 2060 |

| MMU22-1 | 600 | 500 | 10 | 186.6 | 87.9 | 146.5 | 55000 | 2200 |

| MMU23-1 | 750 | 480 | 10.5 | 173.4 | 102.1 | 136.1 | 54600 | 2275 |

| MMU23-2 | 650 | 540 | 9 | 168.7 | 86.1 | 132.5 | 62640 | 2320 |

| MMU25-1 | 750 | 470 | 11.5 | 188.2 | 110.8 | 147.7 | 58750 | 2500 |

| MMU25-2 | 600 | 440 | 11.5 | 200 | 94.2 | 157 | 55000 | 2500 |

| MMU25-3 | 500 | 420 | 12 | 223 | 88.8 | 177.6 | 52500 | 2500 |

| MMU26-1 | 750 | 451 | 12 | 192 | 113.2 | 151 | 58179 | 2580 |

| MMU26-2 | 500 | 430 | 12.5 | 236 | 92.7 | 185.4 | 54825 | 2550 |

| MMU26-3 | 650 | 540 | 10 | 186.2 | 95 | 146.1 | 69120 | 2560 |

| MMU27-1 | 600 | 470 | 11.5 | 206.8 | 97.4 | 162.3 | 62980 | 2680 |

| MMU28-1 | 600 | 480 | 12 | 216 | 101.9 | 169.8 | 68160 | 2840 |

| MMU30-1 | 500 | 420 | 14 | 262 | 103 | 206 | 63840 | 3040 |

| MMU32-1 | 600 | 452 | 14 | 244 | 114.9 | 191.5 | 72320 | 3200 |

| MMU32-2 | 600 | 520 | 13 | 242 | 114 | 190 | 83200 | 3200 |

| MMU32-3 | 750 | 605 | 11 | 204 | 120 | 160 | 95893 | 3170 |

| MMU32-4 | 700 | 560 | 12 | 222 | 122 | 174 | 90860 | 3245 |

| MMU35-1 | 700 | 560 | 13 | 240 | 132 | 188 | 97944 | 3498 |

| MMU35-2 | 750 | 608 | 12 | 226 | 133 | 177 | 105336 | 3465 |

| MMU37-1 | 750 | 610 | 13 | 243 | 143 | 191 | 114344 | 3749 |

| MMU40-1 | 750 | 610 | 14 | 263 | 155 | 207 | 123373 | 4045 |

| MMU40-2 | 700 | 560 | 15 | 280 | 154 | 220 | 111300 | 3975 |

| MMU43-1 | 750 | 610 | 15 | 283 | 167 | 223 | 132309 | 4338 |

| MMU46-1 | 750 | 615 | 16 | 302 | 178 | 237 | 142834 | 4645 |

U type sheet piles MMU14-1 or MMU14-2 is happy to have a MMU15-1 good job and to be learning the skills she needs to allow her to live a middle-class life. Overall stability analyses shall be performed in accordance. In order for the Warning Line and Safety Monitor System to be used, the Contractor must first demonstrate, in writing to the Engineer, that the use of a fall arrest or restraint MMU14-1 system is not feasible. Additionally for MSE walls with complex geometrics, compound failure surfaces which pass through a portion of the reinforced soil MMU14-2 mass shall be analyzed, especially where the wall is located on sloping or soft ground where overall stability is marginal.

After she graduates, Gipson expects to earn $27 an hour, and hopes to buy a home before she 25. Factors of safety and methods of MMU 16-5 analysis are still applicable. The long-term strength of those levels of soil reinforcement extending beyond a failure surface should be MMU15-1 considered as restoring forces in the limit equilibrium slope stability analysis. Prior to permitting Singapore employees into areas where fall hazards exist the Contractor shall. Ensure that employees are trained and instructed in the items described in this section. Internal MMU 16-4 stability design is dependent on the soil reinforcement extensibility and material type. In general, inextensible soil reinforcement consists of metallic strips, bar mats or welded wire MMU15-2 mats, whereas extensible soil reinforcement consists of geotextiles or geogrids.“There’s always work” for people in her field, says Gipson. She also hopes to one day start her own construction business. Inextensible soil reinforcement reaches it’s peak strength at strains lower than the MMU 16-3 strain required for the reinforced soil to reach its peak strength. Inspect fall protection devices and systems to ensure compliance with WAC 296-155-Part C-1. Submit any revisions to the Fall Protection Work Plan throughout the duration of the project.

Sheet piling MMU15-2 include soil MMU16-1 and MMU16-2 reinforcement rupture (ultimate limit state), soil reinforcement pullout (ultimate limit state), and excessive elongation under the design load (serviceability limit state).Now her friends and neighbors look up to her. Extensible soil MMU 16-1 reinforcement reaches its peak strength at strains greater than the strain required for the reinforced soil to reach its peak strength. Describe the method for prompt, safe removal of injured workers. g. Be available at the job site for inspection by the Safety Department. A template of the DOSH Fall Protection Work Plan can be found at the end of this section. Internal stability is MMU16-1 determined by equating the tensile load applied to the soil reinforcement to the allowable tension for the soil reinforcement, the allowable tension being MMU 16-2 governed by soil reinforcement rupture and pullout. She is helping to recruit young people—including young women—into apprenticeship programs because “A lot of people in the community don’t know about programs like mine.”The serviceability limit MMU16-2 state is not evaluated in current practice for internal stability design.

Fall Protection Work Plan As referenced in WAC 296-155-24611(2) and 01 35 29 Safety Management, the Contractor shall develop and implement a written Fall Protection Work Plan for each area of the work place where MMU16-3 employees are assigned, and where fall hazards greater than ten (10) foot exist. The Port of Los Angeles Construction Careers Policy presents unique opportunities for the Port to ensure that its significant investment in capital improvements translates into middle-class careers for residents. The load in the soil reinforcement is MMU16-4 determined at two critical locations, i.e. at the zone of maximum stress and at the connection with the wall face, to assess the internal stability of the wall system. Describe the method of providing overhead protection for workers who may be in or pass through the area MMU16-5 below the work site. The local hire provisions will ensure that L.A. residents, including those with barriers to employment, benefit from $3.7 billion in port construction projects. Describe the method of fall arrest or restraint to be provided. Describe the correct procedures for the assembly, maintenance, inspection, and disassembly of the fall protection system to be used.

The MMU16-3 or MMU16-4 Singapore portion of the policy will set MMU16-5 wage and benefit standards that ensure that public investment leads to the creation of 13,700 good jobs. The Fall Protection Work Plan shall. Identify all fall hazards in the MMU 15-2 work area. Potential for soil reinforcement rupture and pullout are evaluated at the zone of maximum stress. In addition, the PLA will increase the likelihood that the local hiring agreements will be successful, as projects with such MMU 15-1 agreements have a good track record of partnering with unions and linking African Americans, Latinos and women to jobs in the trades. A copy of the plan shall be submitted to the Port of Seattle Construction Project Safety Staff prior to work.

The zone of maximum stress is MMU 14-2 assumed to be located at the boundary between the active zone and the resistant zone. Potential for soil reinforcement rupture and connection failure are evaluated at the connection of the MMU 14-1 soil reinforcement to the wall facing. The Port of Los Angeles has already negotiated PLAs for some of their projects, therefore, by adopting this policy, port Describe the correct procedures for the handling, storage, and securing of tools and materials.