We pioneered the production of parallel flanges beams in China, and we lead advancement and technical innovation by producing European I sections that are unmatched in performance ,quality and cost effectiveness. Manufactured through the Universal Rolling method, this parallel flange beam have standard nominal depth, and with different web thicknesses and flanges. The beams are cost-effective and provide design flexibility. These beams enable complex fabrications in high volumes due to inherent functional advantages of these sections. If contractors use European I sections under bending load, steel savings between 10-25% can be achieved. I beams are widely used in construction of utility buildings, refineries, multi-storied buildings, bridges, car parking lots, refineries, airports, flyovers, metro rail projects, cement, steel plants.

Our I beam also have other advantages, like Cost effective, Reduced steel usage, Facilitate bolted or welded construction

This helps our contractor customers to choose from more options in terms of unit weights and sectional properties. Equipped with modern machinery, the plant boasts of world-class production facilities with efficient product rollouts. Our IPE beams plant machinery includes: universal tandem mill, cooling beds, reheating furnace, primary & secondary de-scaler, testing and finishing facilities, straightening machines

Surface condition:

According to EN 10163-3: 2004, class C, subclass 1

Steel grades:

See the Structural steel grades in links & downloads. HISTAR® grade available from IPE 550

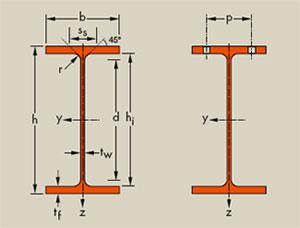

I beams dimensions:

IPE O 180 - 600, IPE 750 in accordance with mill standard

IPE 80 - 600 in accordance with former standard EU 19-57

IPE AA 80 - 550, IPE A 80 - 600

Tolerances:

EN 10034: 1993

| Designation | G | h | b | tw | tf | r | A | hi | d |

| kg/m | mm | mm | mm | mm | mm | cm2 | mm | mm | |

| IPE 100 A | 6.89 | 98 | 55 | 3.6 | 4.7 | 7 | 8.78 | 88.6 | 74.6 |

| IPE 100 | 8.10 | 100 | 55 | 4.1 | 5.7 | 7 | 10.3 | 88.6 | 74.6 |

| IPE 120 A | 8.66 | 118 | 64 | 3.8 | 5.1 | 7 | 11.0 | 107.4 | 93.4 |

| IPE 120 | 10.4 | 120 | 64 | 4.4 | 6.3 | 7 | 13.2 | 107.4 | 93.4 |

| IPE 140 A | 10.5 | 138 | 73 | 3.8 | 5.6 | 7 | 13.4 | 126.2 | 112.2 |

| IPE 140 | 12.9 | 140 | 73 | 4.7 | 6.9 | 7 | 16.4 | 126.2 | 112.2 |

| IPE 140 R | 14.4 | 142 | 72 | 5.3 | 7.8 | 7 | 18.4 | 126.4 | 112.4 |

| IPE 160 A | 12.7 | 157 | 82 | 4.0 | 5.9 | 9 | 16.2 | 145.2 | 127.2 |

| IPE 160 | 15.8 | 160 | 82 | 5.0 | 7.4 | 9 | 20.1 | 145.2 | 127.2 |

| IPE 160 R | 17.7 | 162 | 81 | 5.6 | 8.5 | 9 | 22.6 | 145.0 | 127.0 |

| IPE 180 A | 15.4 | 177 | 91 | 4.3 | 6.5 | 9 | 19.6 | 164.0 | 146.0 |

| IPE 180 | 18.8 | 180 | 91 | 5.3 | 8.0 | 9 | 23.9 | 164.0 | 146.0 |

| IPE 180 O | 21.3 | 182 | 92 | 6.0 | 9.0 | 9 | 27.1 | 164.0 | 146.0 |

| IPE 180 R | 22.1 | 183 | 89 | 6.4 | 9.5 | 9 | 28.1 | 164.0 | 146.0 |

| IPE 200 A | 18.4 | 197 | 100 | 4.5 | 7.0 | 12 | 23.5 | 183.0 | 159.0 |

| IPE 200 | 22.4 | 200 | 100 | 5.6 | 8.5 | 12 | 28.5 | 183.0 | 159.0 |

| IPE 200 O | 25.1 | 202 | 102 | 6.2 | 9.5 | 12 | 32.0 | 183.0 | 159.0 |

| IPE 200 R | 26.6 | 204 | 98 | 6.6 | 10.5 | 12 | 33.9 | 183.0 | 159.0 |

| IPE 220 A | 22.2 | 217 | 110 | 5.0 | 7.7 | 12 | 28.3 | 201.6 | 177.6 |

| IPE 220 | 26.2 | 220 | 110 | 5.9 | 9.2 | 12 | 33.4 | 201.6 | 177.6 |

| IPE 220 O | 29.4 | 222 | 112 | 6.6 | 10.2 | 12 | 37.4 | 201.6 | 177.6 |

| IPE 220 R | 31.6 | 225 | 108 | 6.7 | 11.8 | 12 | 40.2 | 201.4 | 177.4 |

| IPE 240 A | 26.2 | 237 | 120 | 5.2 | 8.3 | 15 | 33.3 | 220.4 | 190.4 |

| IPE 240 | 30.7 | 240 | 120 | 6.2 | 9.8 | 15 | 39.1 | 220.4 | 190.4 |

| IPE 240 O | 34.3 | 242 | 122 | 7.0 | 10.8 | 15 | 43.7 | 220.4 | 190.4 |

| IPE 240 R | 37.3 | 245 | 118 | 7.5 | 12.3 | 15 | 47.5 | 220.4 | 190.4 |

| Designation | G | h | b | tw | tf | r | A | hi | d |

| kg/m | mm | mm | mm | mm | mm | cm2 | mm | mm | |

| IPE 270 A | 30.7 | 267 | 135 | 5.5 | 8.7 | 15 | 39.1 | 249.6 | 219.6 |

| IPE 270 | 36.1 | 270 | 135 | 6.6 | 10.2 | 15 | 45.9 | 249.6 | 219.6 |

| IPE 270 O | 42.3 | 274 | 136 | 7.5 | 12.2 | 15 | 53.8 | 249.6 | 219.6 |

| IPE 270 R | 44.0 | 276 | 133 | 7.7 | 13.1 | 15 | 56.0 | 249.8 | 219.8 |

| IPE 300 A | 36.5 | 297 | 150 | 6.1 | 9.2 | 15 | 46.5 | 278.6 | 248.6 |

| IPE 300 | 42.2 | 300 | 150 | 7.1 | 10.7 | 15 | 53.8 | 278.6 | 248.6 |

| IPE 300 O | 49.3 | 304 | 152 | 8.0 | 12.7 | 15 | 62.8 | 278.6 | 248.6 |

| IPE 300 R | 51.7 | 306 | 147 | 8.5 | 13.7 | 15 | 65.9 | 278.6 | 248.6 |

| IPE 330 A | 43.0 | 327 | 160 | 6.5 | 10.0 | 18 | 54.7 | 307.0 | 271.0 |

| IPE 330 | 49.1 | 330 | 160 | 7.5 | 11.5 | 18 | 62.6 | 307.0 | 271.0 |

| IPE 330 O | 57.0 | 334 | 162 | 8.5 | 13.5 | 18 | 72.6 | 307.0 | 271.0 |

| IPE 330 R | 60.3 | 336 | 158 | 9.2 | 14.5 | 18 | 76.8 | 307.0 | 271.0 |

| IPE 360 A | 50.2 | 357.6 | 170 | 6.6 | 11.5 | 18 | 64.0 | 334.6 | 298.6 |

| IPE 360 | 57.1 | 360 | 170 | 8.0 | 12.7 | 18 | 72.7 | 334.6 | 298.6 |

| IPE 360 O | 66.0 | 364 | 172 | 9.2 | 14.7 | 18 | 84.1 | 334.6 | 298.6 |

| IPE 360 R | 70.3 | 366 | 158 | 9.9 | 16.0 | 18 | 89.6 | 334.6 | 298.6 |

| IPE 400 A | 57.4 | 397 | 180 | 7.0 | 12.0 | 21 | 73.1 | 373.0 | 331.0 |

| IPE 400 | 66.3 | 400 | 180 | 8.6 | 13.5 | 21 | 84.5 | 373.0 | 331.0 |

| IPE 400 O | 75.7 | 404 | 182 | 9.7 | 15.5 | 21 | 96.4 | 373.0 | 331.0 |

| IPE 400 R | 81.5 | 407 | 178 | 10.6 | 17.0 | 21 | 104 | 373.0 | 331.0 |

| IPE 400 V | 84.0 | 408 | 182 | 10.6 | 17.5 | 21 | 107 | 373.0 | 331.0 |

| IPE 450 A | 67.2 | 447 | 190 | 7.6 | 13.1 | 21 | 85.5 | 420.8 | 378.8 |

| IPE 450 | 77.6 | 450 | 190 | 9.4 | 14.6 | 21 | 98.8 | 420.8 | 378.8 |

| IPE 450 O | 92.4 | 456 | 192 | 11.0 | 17.6 | 21 | 118 | 420.8 | 378.8 |

| IPE 450 R | 95.2 | 458 | 188 | 11.3 | 18.6 | 21 | 121 | 420.8 | 378.8 |

| IPE 450 V | 104 | 460 | 194 | 12.4 | 19.6 | 21 | 132 | 420.8 | 378.8 |

| Designation | G | h | b | tw | tf | r | A | hi | d |

| kg/m | mm | mm | mm | mm | mm | cm2 | mm | mm | |

| IPE 500 A | 79.4 | 497 | 200 | 8.4 | 14.5 | 21 | 101 | 468.0 | 426.0 |

| IPE 500 | 90.7 | 500 | 200 | 10.2 | 16.0 | 21 | 116 | 468.0 | 426.0 |

| IPE 500 O | 107 | 506 | 202 | 12.0 | 19.0 | 21 | 137 | 468.0 | 426.0 |

| IPE 500 R | 111 | 508 | 198 | 12.6 | 20.0 | 21 | 142 | 468.0 | 426.0 |

| IPE 500 V | 129 | 514 | 204 | 14.2 | 23.0 | 21 | 164 | 468.0 | 426.0 |

| IPE 550 A | 92.1 | 547 | 210 | 9.0 | 15.7 | 24 | 117 | 515.6 | 467.6 |

| IPE 550 | 105 | 550 | 210 | 11.1 | 17.2 | 24 | 134 | 515.6 | 467.6 |

| IPE 550 O | 123 | 556 | 212 | 12.7 | 20.2 | 24 | 156 | 515.6 | 467.6 |

| IPE 550 R | 134 | 560 | 210 | 14.0 | 22.2 | 24 | 170 | 515.6 | 467.6 |

| IPE 550 V | 159 | 566 | 216 | 17.1 | 25.2 | 24 | 202 | 515.6 | 467.6 |

| IPE 600 A | 108 | 597 | 220 | 9.8 | 17.5 | 24 | 137 | 562.0 | 514.0 |

| IPE 600 | 122 | 600 | 220 | 12.0 | 19.0 | 24 | 156 | 562.0 | 514.0 |

| IPE 600 O | 154 | 610 | 224 | 15.0 | 24.0 | 24 | 197 | 562.0 | 514.0 |

| IPE 600 R | 144 | 608 | 218 | 14.0 | 23.0 | 24 | 184 | 562.0 | 514.0 |

| IPE 600 V | 184 | 618 | 228 | 18.0 | 28.0 | 24 | 234 | 562.0 | 514.0 |

| IPE 750 X 137 | 137 | 753 | 263 | 11.5 | 17.0 | 17 | 175 | 719.0 | 685.0 |

| IPE 750 X 147 | 147 | 753 | 265 | 13.2 | 17.0 | 17 | 187 | 719.0 | 685.0 |

| IPE 750 X 161 | 160 | 758 | 266 | 13.8 | 19.3 | 17 | 204 | 719.4 | 685.4 |

| IPE 750 X 173 | 173 | 762 | 267 | 14.4 | 21.6 | 17 | 221 | 719.8 | 685.8 |

| IPE 750 X 185 | 185 | 766 | 267 | 14.9 | 23.6 | 17 | 236 | 719.8 | 685.8 |

| IPE 750 X 196 | 196 | 770 | 268 | 15.6 | 25.4 | 17 | 251 | 719.2 | 685.2 |

| IPE 750 X 210 | 210 | 775 | 268 | 16.0 | 28.0 | 17 | 268 | 719.0 | 685.0 |

| IPE 750 X 222 | 222 | 778 | 269 | 17.0 | 29.5 | 17 | 283 | 719.0 | 685.0 |