The HP bearing piles are special bearing piles with the same thickness for flange and web. Weights of rolled sections are computed on the basis that one cubic foot of steel weighs 490 lbs. Weights have been calculated on theoretical dimensions and rounded to the nearest pound.The radii of fillets and rounded edges are likely to change during the rolling process due to roll wear. The listed dimensions of bearing pile generally allow for these wear variations.No limits for the length of the pile, due to an easy adaptation to the soil conditions by splicing.The sections can be delivered in all standard steel grades after agreement.

HP bearing pile is dimensionally square structural beams that are driven in the ground for deep foundation applications. Rolling and cutting tolerances shown in this catalog are in conformance with ASTM A6/A6M.Minimum tonnage of 50 tons, for the sections HP220*57.2;260*75-87.3;400*122-231 derivative section and quality.Excellent durability; numerous experiences for totally embedded piles showed a corrosion rate tending to zero.Steel bearing piles are manufactured and designed to transfer structural loads to these good bearing soils.

Rolling shapes involves factors such as roll wear, subsequent roll dressing, and temperature variations, which cause actual dimensions to vary slightly from the published dimensions, within the permissible ASTM tolerances. Fillets have been included in computations of weights and properties.Control of the steel bearing pile capacity by measurement of the refusal at driving.

Structural shapes distributed by Arcelor sheet Piling are rolled to conform to the latest ASTM Structural Steel Specification. Bearing piles of this type are used all over the world for the deep foundations of various structures: housings, industrial constructions, bridges.H-Piles are also used in conjunction with sheet piles to add lateral stiffness and bending resistance where loads exceed the capacity of sheet piles alone.

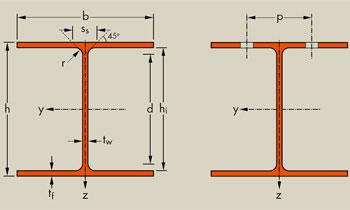

Dimensions:

In accordance with mill standard

Tolerances:

EN 10034: 1993

Surface condition:

According to EN 10163-3: 2004, class C, subclass 1

| Section | Mass (G) | Dimensions | Steel Area (A) | Perimeter | Moment of inertia | Section modulus | |||||

| h | b | tw | tf | y-y | z-z | y-y | z-z | ||||

| kg/m | mm | mm | mm | mm | cm2 | m | cm4 | cm4 | cm3 | cm3 | |

| HP 220 * 57.2 | 57,2 | 210 | 224,5 | 11 | 11 | 72,9 | 1,265 | 5729 | 2079 | 545,6 | 185,2 |

| HP 260 * 87.3 | 87,3 | 253 | 267 | 14 | 14 | 111,2 | 1,505 | 12590 | 4455 | 994,9 | 333,7 |

| HP 260 *7 5 | 75 | 249 | 265 | 12 | 12 | 95,54 | 1,493 | 10650 | 3733 | 855,1 | 281,7 |

| HP 305 * 110 | 110 | 307,9 | 310,7 | 15,3 | 15,4 | 140,2 | 1,8 | 23560 | 7709 | 1531 | 495 |

| HP 305 * 126 | 126 | 312,3 | 312,9 | 17,5 | 17,6 | 161 | 1,813 | 27410 | 9002 | 1755 | 577,2 |

| HP 305 * 149 | 149 | 318,5 | 316 | 20,6 | 20,7 | 190 | 1,832 | 33070 | 10910 | 2076 | 688,8 |

| HP 305 * 180 | 180 | 326,7 | 319,7 | 24,8 | 24,8 | 229,3 | 1,857 | 40970 | 13550 | 2508 | 847,4 |

| HP 305 * 186 | 186 | 328,3 | 320,9 | 25,5 | 25,6 | 237 | 1,861 | 42610 | 14140 | 2596 | 879,3 |

| HP 305 * 223 | 223 | 337,9 | 325,7 | 30,3 | 30,4 | 285 | 1,891 | 52700 | 17580 | 3119 | 1081 |

| HP 305 * 88 | 88 | 301,7 | 307,8 | 12,3 | 12,4 | 111,6 | 1,782 | 18420 | 5984 | 1221 | 387,3 |

| HP 305 * 95 | 95 | 303,7 | 308,7 | 13,3 | 13,3 | 121,7 | 1,788 | 20040 | 6529 | 1320 | 425,1 |

| HP 320 * 103 | 103 | 307 | 306 | 14 | 14 | 131 | 1,764 | 22050 | 6704 | 1437 | 438,2 |

| HP 320 * 117 | 117 | 311 | 308 | 16 | 16 | 149,5 | 1,776 | 25480 | 7815 | 1638 | 507,5 |

| HP 320 * 147 | 147 | 319 | 312 | 20 | 20 | 186,9 | 1,8 | 32670 | 10160 | 2048 | 651,3 |

| HP 320 * 184 | 184 | 329 | 317 | 25 | 25 | 234,5 | 1,83 | 42340 | 13330 | 2574 | 841,2 |

| HP 320 * 88.5 | 88,5 | 303 | 304 | 12 | 12 | 112,7 | 1,752 | 18740 | 5634 | 1237 | 370,6 |

| HP 360 * 109 | 109 | 346,4 | 371 | 12,8 | 12,9 | 138,9 | 2,123 | 30630 | 10990 | 1769 | 590,7 |

| HP 360 * 133 | 133 | 352 | 373,8 | 15,6 | 15,7 | 168,5 | 2,14 | 37980 | 13680 | 2158 | 725,3 |

| HP 360 * 152 | 152 | 356,4 | 376,0 | 17,8 | 17,9 | 193,8 | 2,153 | 43970 | 15880 | 2468 | 842,3 |

| HP 360 * 174 | 174 | 361,4 | 378,5 | 20,3 | 20,4 | 221,7 | 2,169 | 51010 | 18460 | 2823 | 973,5 |

| HP 360 * 180 | 180 | 362,9 | 378,8 | 21,1 | 21,1 | 229,5 | 2,173 | 53040 | 19140 | 2923 | 1011 |

| HP 360 * 84.3 | 84,3 | 340 | 367 | 10 | 10 | 107,3 | 2,102 | 23190 | 8243 | 1364 | 449,2 |

| HP 400 * 122 | 122 | 348 | 390 | 14 | 14 | 155,9 | 2,202 | 34770 | 13850 | 1998 | 710,3 |

| HP 400 * 140 | 140 | 352 | 392 | 16 | 16 | 178,6 | 2,214 | 40270 | 16080 | 2288 | 820,2 |

| HP 400 * 158 | 158 | 356 | 394 | 18 | 18 | 201,4 | 2,226 | 45940 | 18370 | 2581 | 932,4 |

| HP 400 * 176 | 176 | 360 | 396 | 20 | 20 | 224,3 | 2,238 | 51770 | 20720 | 2876 | 1047 |

| HP 400 * 194 | 194 | 364 | 398 | 22 | 22 | 247,5 | 2,25 | 57760 | 23150 | 3174 | 1163 |

| HP 400 * 213 | 213 | 368 | 400 | 24 | 24 | 270,7 | 2,262 | 63920 | 25640 | 3474 | 1282 |

| HP 400 * 231 | 231 | 372 | 402 | 26 | 26 | 294,2 | 2,274 | 70260 | 28200 | 3777 | 1403 |