521. Design of Sheet Pile Size

Sheet pile size in the marine environment like Steel Sheet Pile walls at quays and harbors, undergo continuous corrosion subjected to prolong sea water environment.

520. Free Cantilever Sheet Pile Walls

In the design of the cantilever sheet pile wall, although the Coulomb approach considering wall friction tends to be more realistic, the Rankine approach (with the angle of wall friction δ = 0) is normally used.

519. Sheet pile wall types

The most common types of sheet pile wall used are steel sheet piles.

518. Interlocking Sheet Pile Installation

A commonly used method to realise interlocking sheet pile installation is by using vibratory hammers.

517. Design Guide For Sheet Pile Bridge Abutments

Bridge abutments also have to resist vertical loads from the bridge superstructure, therefore methods to determine the axial capacity of steel sheet pile abutment in different soil types are covered by reference to the SCI publication Steel bearing piles guide.

516. Building a Gravity Sheet Pile Retaining Wall With Stackable Concrete Blocks

Stackable concrete blocks are generally recommended for sheet pile retaining walls less than 3’- 4’ high. Taller sheet pile retaining walls typically need additional structural reinforcement and may require a building permit along with professional advice or help.

515. Perfect solution for all types of sheet pile

From small sheet pile capping beams to very large sheet pile capping beams such as Littlehampton flood defence works where a 1.8m high beam is being cast to raise the flood defence levels, sheet pile capping beam is flexible enough to cope with all types and sizes of sheet pile capping beams.

514. How To Build A Sheet Pile Retaining Wall

An anchored sheet pile retaining wall can be constructed in any of the aforementioned styles but also includes additional strength using cables or other stays anchored in the rock or soil behind it.

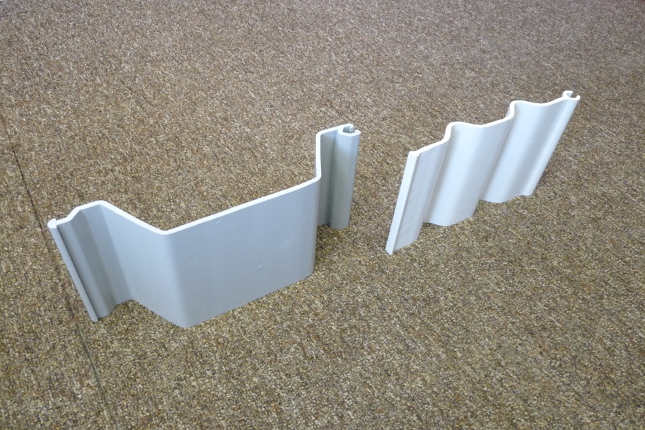

513. PLASTIC PILING SHEET

Similar in appearance to some steel sheet piles, the plastic piling sheet is extremely versatile and easy to install.

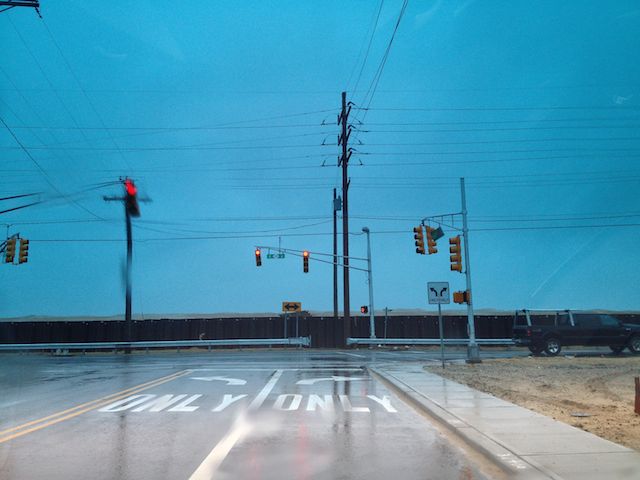

512. Steel Sheet Pile Wall Dunes Restoration

In order to prevent a breach of the barrier island during a storm, we associates to install a 4 mile long steel sheet pile wall within the sand dunes on the beach in Mantoloking.

511. Installation of sheet pile dimensions

There is an acceptable number of ‘under-driven’ sheet pile dimensions, but this will vary according to the specific design requirements.

510. Sheet pile and cofferdam

One of the easiest and quickest ways in which to form a watertight retaining wall, in soft or loose saturated soil profiles, is to use sheet pile cofferdam.

509. Interlocking Sheet Pile Retention Systems

We use a wide range of interlocking sheet pile systems that are designed and manufactured to suit a wide range of projects. We also manufacture our own light weight interlocking sheet pile.

508. Push pull system of steel sheet pile

We offer a silent piling pressing push pull system technique, which starts working when powerful hydraulic clamps take hold of the tops of several interlocked steel sheet piles.

507. Sheet pile construction method classification

This is achieved by the vertical vibration generated by the vibration pile hammer steel sheet pile driven into the ground construction technology.

506. What are the requirements for the height of the sheet pile?

The height of the cofferdam of the sheet pile for sale must be higher than the maximum water level that may occur during construction, including the height of the wave, at least 0.5-0.7 meters above it.

505. Structural Steel Shape Sheet pile

Steel sheet pile is classified in two construction applications, permanent and temporary.

504. Sheet Pile Shoring Wall Systems

Sheet pile shoring systems are walls that are formed in progressive manner within the ground by constructing a sequence of piles along the outline of the site and used to laterally retain ground including soil, rock and groundwater.

503. Sheet Pile Walls

Primary sheet piles are made of C8/10 concrete containing added bentonite (waterproofing role) and the secondary (strength) sheet piles are made of C25/30 concrete, reinforced vertically by 8 independent 25 mm diameter bars and a 10 mm diameter spiral reinforcement.

502. KRINGS Sheet pile machine DPV

If the trench is crossed by cables or pipes, the sheet pile in question is locked in position above the cable or pipe while the other sheet piles are pressed past the obstacle into the ground.