541. Earth Pressure against Sheet Pile

Sheet piling is the most common type of flexible earth retaining systems used as waterfront structures.

540. Sheet piling walls

Cantilever sheet piling walls depend on the passive resisting capacity of the soil below the depth of excavation to prevent overturning.

539. Steel Sheet Piling Corrosion and Protection

In marine construction environments, steel sheet pilings are exposed to a host of natural influences that can impact their useful service lives.

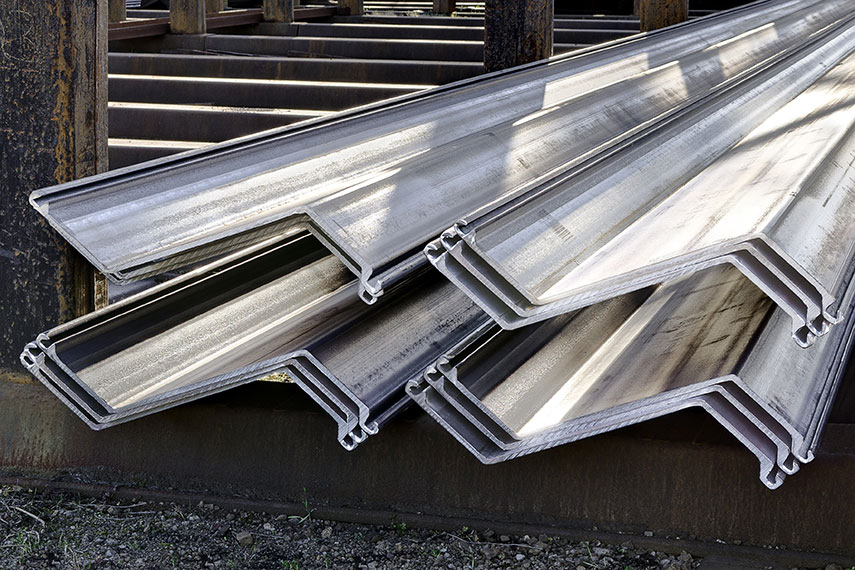

538. Steel Sheet Piling is roll-formed for a continuous, positive interlock.

Our steel sheet piling is available in a variety of different gauges, weights and lengths to suit almost any new construction or rehabilitation application.

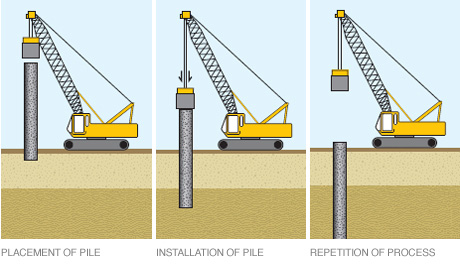

537. Definition of sheet pile

Sheet pile installation driving dimensions wall design cost retaining walls structures designed restrain soil unnatural slopes they used bound soils between steel piling.

536. The diversity of sheet pile specifications

Leading the way in custom steel fabrication for construction projects across China, we have premium experience as the supplier of sheet piles.

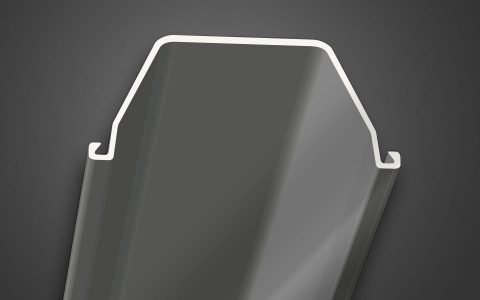

535. Introduction of interlocking sheet pile

All of ourinterlocking sheet pile according ASTM A 328, ASTM A 690 standards.

534. Piling Sheets Manufacturer from Nanjing

Our organization gained specialize in developing and offering a wide range of piling sheets.

533. Specification for sheet pile

The Contractor shall submit with his tender all relevant details of the method of construction of the sheet pile dimensions wall and the plant and monitoring equipment he plans to adopt.

532. Failure Of Sheet Pile Retaining Wall When Struts Were Removed

Before the gap between the sheet piles and the basement wall were backfilled, workers proceeded to remove the struts and walers to facilitate construction of the next level.

531. Metal Sheet Pile Corrosion and Protection

Because damage stemming from corroded metal sheet pile can be significant, an understanding of corrosion factors, zones, and preventive measures is paramount to sustaining a piling's long-term life.

530. Design Of Driving Sheet Pile Walls

Both of these are addressed in established methods used to compute the strength and overturning resistance of driving sheet piles.

529. Braced sheet pile shoring wall in sensitive clay

The braced sheet pile wall was designed using the Terzaghi Apparent Earth Pressure distribution and conventional limit equilibrium analysis methods.

528. Piling sheet for sale in nigeria

We offer a piling sheet pressing push pull system technique, which starts working when powerful hydraulic clamps take hold of the tops of several interlocked piling sheet.

527. U Steel Sheet Piling

The U-shaped Steel Sheet Pile has been used for ground support for over 100 years, their versatility, reliability and strength has been paramount to their success and constant use in the construction industry.

526. Method for cantilever sheet pile connection

In EP 0898021 was asked to implement a fixed connection between two cantilever sheet piles compression of the external connection parts formed by members with each other into engagement locks piles.

525. What is involved in the cost of a sheet pile seawall?

This includes the materials used in the building of your sheet pile seawall (vinyl sheet piling, concrete, steel, etc.) as well as the materials required in the preparation, installation, and transportation of your sheet pile seawall product.

524. Cantilever sheet pile – Lighter, Wider, Stronger

The cantilever sheet pile is the optimal section for weight and strength, coupled with driveability.

523. Sheet Pile in the Philippines

Sheet piles NEED to be of high quality so to assure that the walling is firm and can withstand with various intensity of forces. It is one of the most trusted the supplier of sheet piles Philippines, especially for multi national companies, government infrastructures, among others.

522. Mitigation of existing structure settlement by sheet pile walls when liquefaction

Combined adaptation of sheet pile walls installation with a decrease in groundwater level engenders a great degree of reduction in the settlement of structures than with adaptation of the single technique of the sheet pile wall installation or dewatering of GWL.