88. The advantages of steel sheet piling

Steel sheet piling is a hot-rolled structural shape with interlocks on the flange tips. The interlocks permit individual sections to be connected to form a continuous steel wall which is earth-tight and water resistant. Because it is readily available and transportable, sheet piling is in many cases a fast and economical solution to an owner’s need for a durable, long lasting wall system.

87. Trench sheeting

We offer a complete service, from initial consultation to the supply of quality manufactured trench sheeting. Our unrivalled range of sheets and advanced processing services will help you to develop innovative and robust solutions.

86. What is Soil Nailing?

Soil nailing is a technique used to bring soil stability in areas where landslides might be a problem. Soil nail can prevent landslides by inserting steel reinforcement bars into the soil and anchoring them to the soil strata.

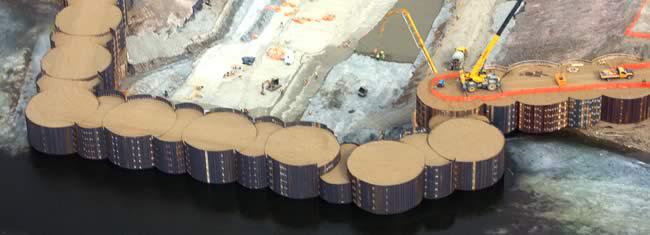

85. Steel Sheet Piles for Cofferdams

The advanced cold forming process utilized in the manufacture of Steel's sheet piles ensures a watertight seal that effectively contains soil and debris in a variety of site conditions.

84. What are Marine Tie Rods and Why Do They Break?

Marine engines are fabricated with different components, which are held and tied together to complete the engine structure with the help of marine tie rods. As the name suggest, marine tie rods are long metal rods that are generally found at the periphery of the engine.

83. A brief description of Pipe Piling

We deliver standard pipe piles, micro piles, pin piles, marine piles, and other steel pipe piles for deep foundation construction piling projects. Pipe Piles provide support for geotechnical and deep foundation projects with friction pipe piles, load bearing piles, driven pipe piles, straight seam piles and end-bearing applications.

81. Cold Rolled Steel Sheet Pile Sections

Steel Sheet Piling has a connection “interlock” at both ends of the section. These interlocks connect with one another to form a continuous wall of sheet piling.

80. APPLICATIONS OF SHEET PILE WALLS

Sheet piling systems comprises developed sheet pile sections with either an overlapping joints or an interlocking one (Fig.1-c). The sections can either be cantilevered to support the excavation, depending on the imposed loads, or they can be restrained by a specially designed mechanism with anchor.

79. Hot rolled sheet piles

We offers both hot-rolled and cold-formed sheet piling. Hot-rolled steel is rougher than cold-rolled steel.

78. Steel Manufacturing Process

Advanced cold form manufacturing processes utilizes proven press braking technology, allowing engineers to form a variety of precisely bent shapes from flat plates of cold rolled steel.

77. Sheet Piles Construction

Steel sheet pile walls are constructed by driving steel sheets into a slope or excavation. Their most common use is within temporary deep excavations. They are considered to be most economical where retention of higher earth pressures of soft soils is required.

76. Non Ferrous Sheet Piles

Vinyl sheet piles, Fibre Reinforced Plastic sheet piles and Aluminium sheet piles are manufactured in similar shapes and section modulus to steel sheet piles.

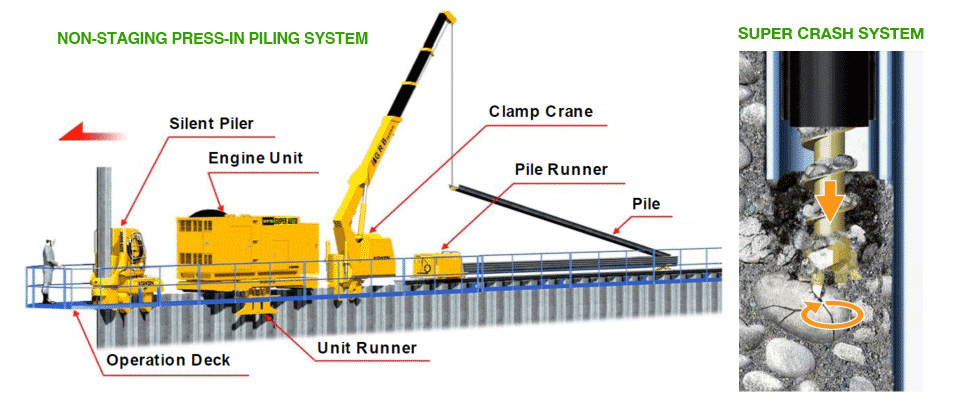

75. How To Install Sheet Pile

Contractors use sheet pile as a temporary supportive wall which is used to support the soft soil collapsed from higher ground to lower ground. Sheet pile is commonly used in the construction and has variety types of material for sheet pile.

73. Cognitive rock bolt

Rock bolts,in tunneling and underground mining, steel rod inserted in a hole drilled into the roof or walls of a rock formation to provide support to the roof or sides of the cavity.

72. Sheet pile design - sheet pile

The image above shows a sheet pile design with two levels of struts for a cofferdam inside a water body. The AZ48 sheet pile walls are designed to resist bending moments, while the sheet pile design capacity is shown with the red lines next to the bending moment diagrams.

71. Fiberglass Sheet Piles Information

There are three types of composite sheet piles, light piles, heavy duty sheet piles and super heavy duty piles. The length, width, wall thickness and materials will decide the strength of sheet pile. Common shapes of sheet piles are Z-pile and box pile.

69. Learn How Composite Sheet Piling Can Save You Money

A special marine-grade resin system locks in the thousands of interwoven rovings and mattings to produce a sheet piling that can withstand the toughest conditions. Still unsure of composites – just ask the Boeing engineers who have designed the new 787 with over 80% composite material!

68. Tie Rods

Tie rods can be used in conjunction with a typical sheet pile retaining system to provide additional support and stability for walls that may be too high to be cantilevered.

67. Pipe Piles Properties

Similar to H-Piles, Pipe Piles are also

designed to transfer structural loads

through the foundation to soils below.

point bearing, Pipe Piles are most

substantial surface area that interacts

with the surrounding soil to provide

great frictional load resistance.

66. Spiral Welded Steel Pipe Piles

Spiral Welded Steel Pipe Piles is used universally as a steel pile for piles. It can be used for foundation piling for buildings, harbour construction including wharves, jetties, as well as bridges and water pipes etc.