130. What is Steel Sheet Piling?

Steel sheet piling is a rolled structural steel section with interlocks on the flange tips which enable the joining of sections to form a continuous wall.

129. Sheet Piles

Sheet pile is a hot or cold rolled structural shape with interlocks on the flange tips. The interlocks permit individual sections to be connected in order to form a continuous steel wall which is earth tight and virtually water resistant.

128. Synthetic Flood Walls Offer Protection

We would like to help you lower project costs and provide better flood protection for your projects. Our team has worked on hundreds of crucial flood protection projects. Leverage our experience and learn how to value engineer traditional designs with synthetic sheet piling.

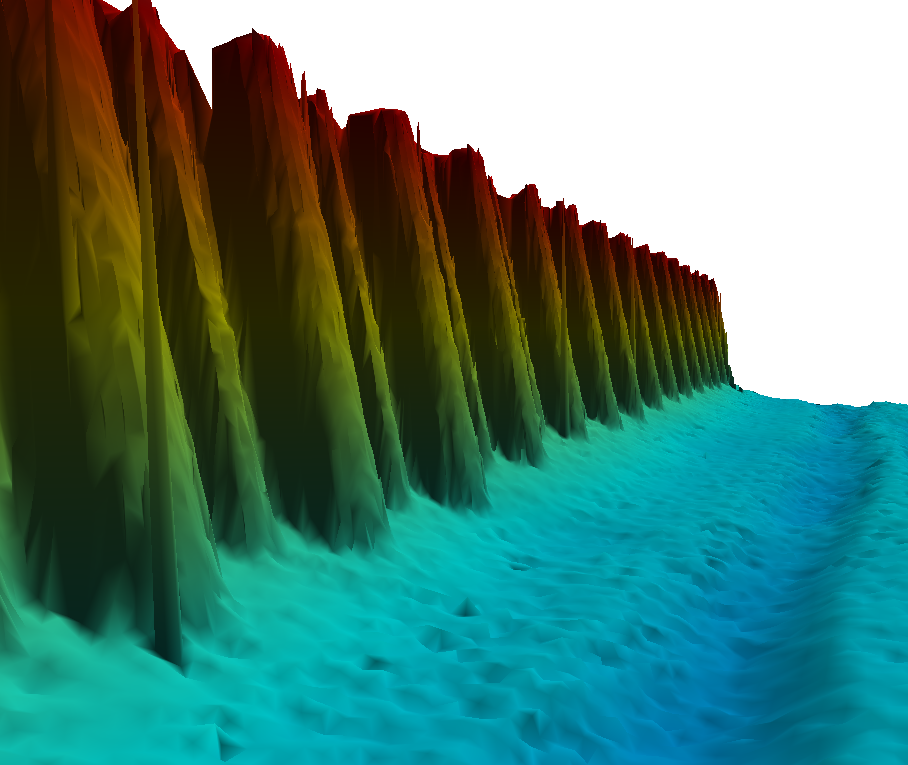

127. Development of Design Properties for the Seawall-Sheet pile

Material strength comparisons are not sufficient to determine the capacity of the FRP sheet pile. This paper shows the Pre-Standard buckling calculations or FEA are both options for determining conservation strength capacities of the assembled structure.

126. Combined steel sheet pile wall system

The main function of the sheet piles is to transmit earth and water pressures to the tubes.

125. Vibro Sheet Pile Drivers

We supplies the vibro sheet pile driver range that makes the installation of sheet piles much easier. Turn your excavator into a high-performance sheet pile driver and get sheet pile driving at a lower capital cost.

124. LATERAL PRESSURES ON SHEET PILE

Earth pressure against a sheet pile structure is not a unique function for each soil, but rather a function of the soil-structure system. Accordingly, movements of the structure are a primary factor in developing earth pressures. The problem, therefore, is highly indeterminate.

123. Development of pile driving methods

Sheet pile which has already been driven into ground is used as the reaction to push another sheet pile statically into the ground. This method is suitable for low-vibration, low-noise pile-driving at construction sites in urban areas and for pile-driving at confined construction sites.

122. Pile driving equipment-Sheet Pile

BHS (Bulkhead Select) steel sheet pile is new steel sheet pile with guaranteed properties that are competitive in price with used steel sheet pile.

121. sheet pile of past and future

The history of sheet piling goes back to the beginning of the last century. Over the years, ongoing development in steel grades, section shapes ans driving techniques have led to a wide range of applications for sheet piling.

120. Gerdau Ameristeel Steel Sheet Piling

These steel sheet piling sections can be used for beam strength or interlock strength for applications including river cofferdams, retaining walls, foundations, levee construction, bridge abutments, bridge pier protection, and more.

119. Types of retaining wall

Sheet pile retaining walls are usually used in soft soils and tight spaces. Sheet pile walls are made out of steel, vinyl or wood planks which are driven into the ground. For a quick estimate the material is usually driven 1/3 above ground, 2/3 below ground, but this may be altered depending on the environment.

118. Steel Sheet Piling

Our Steel Sheet Piling is roll-formed with a continuous, positive interlock. Easy-to-install in many soil conditions, our Sheet Piling system has the largest section modulus available for comparable lightweight piling.

117. Points and Notices in Sheet Pile Construction Process

Lift sheet pile and with the worker’s help, put it into the last piled one’s locking mouth, sink to earth under its own weight, and then pull the vibratory hammer to fight on the pile.

116. Installation of Steel Sheet Piling

Steel sheet piling is frequently an ideal solution both as regards structural considerations and driving conditions, which is also capable of absorbing localized overloading without endangering overall stability.

115. Analysis of sheet pile wall

A sheet pile wall is analyzed using a standard approach that account for the effect of earth pressures. In general, the active earth pressure develops behind the structure while the passive earth pressure appears in front of the structure.

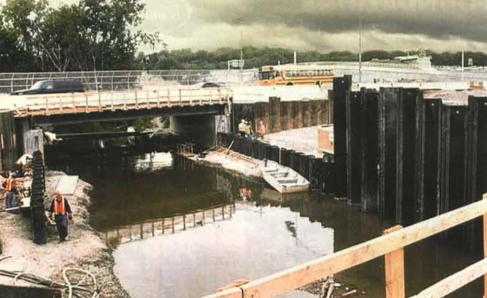

114. The application of steel sheet pile cofferdam in the tunnel project of China

Since the plan’s optimization, from building three sheet pile cofferdams to only one cofferdam and use the new construction method of sheet pile cofferdam, anchorage pile and the technological application of ultrasonic determine apparatus, it saves more than 3 months for the whole project.

113. Straight web sections

Straight web sheet piles are designed to form cylindrical structures, generally closed, retaining a soil backfill. The stability of constructions built up like that is guaranteed by the weight of the internal soil massive.

112. Longevity and Sustainability-Sheet Pile

With regard to sheet pile bridge abutments, steel piles in fresh water lose less than 1/6 in. Of thickness due to corrosion in the zone of high attack after 100 years of life, without any surface coating or maintenance required.

111. Tie-rod anchorage

sheet pile plates or continuous anchor walls, made from sheet piles, are to be used, it is sufficient to excavate up to anchor level.